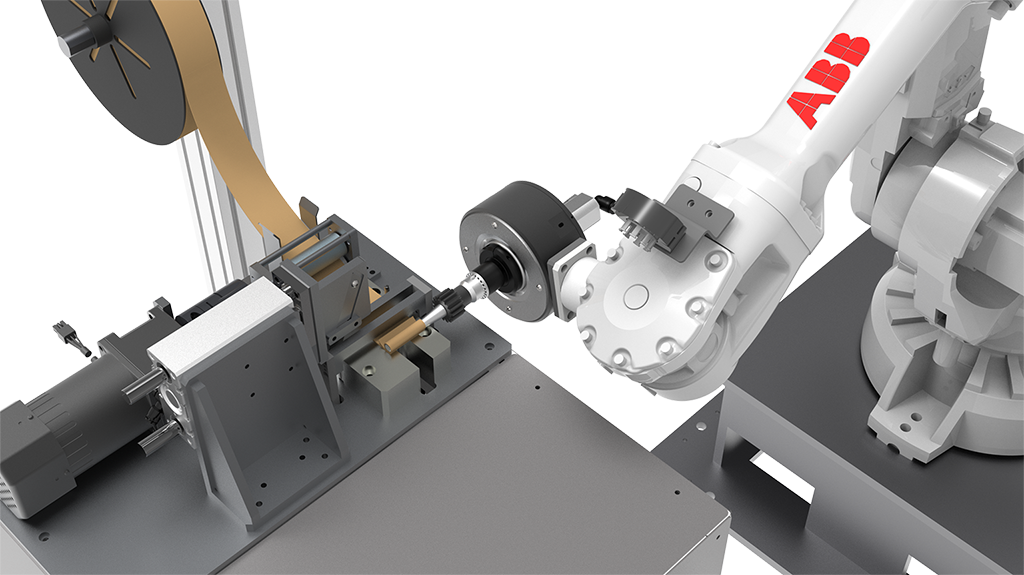

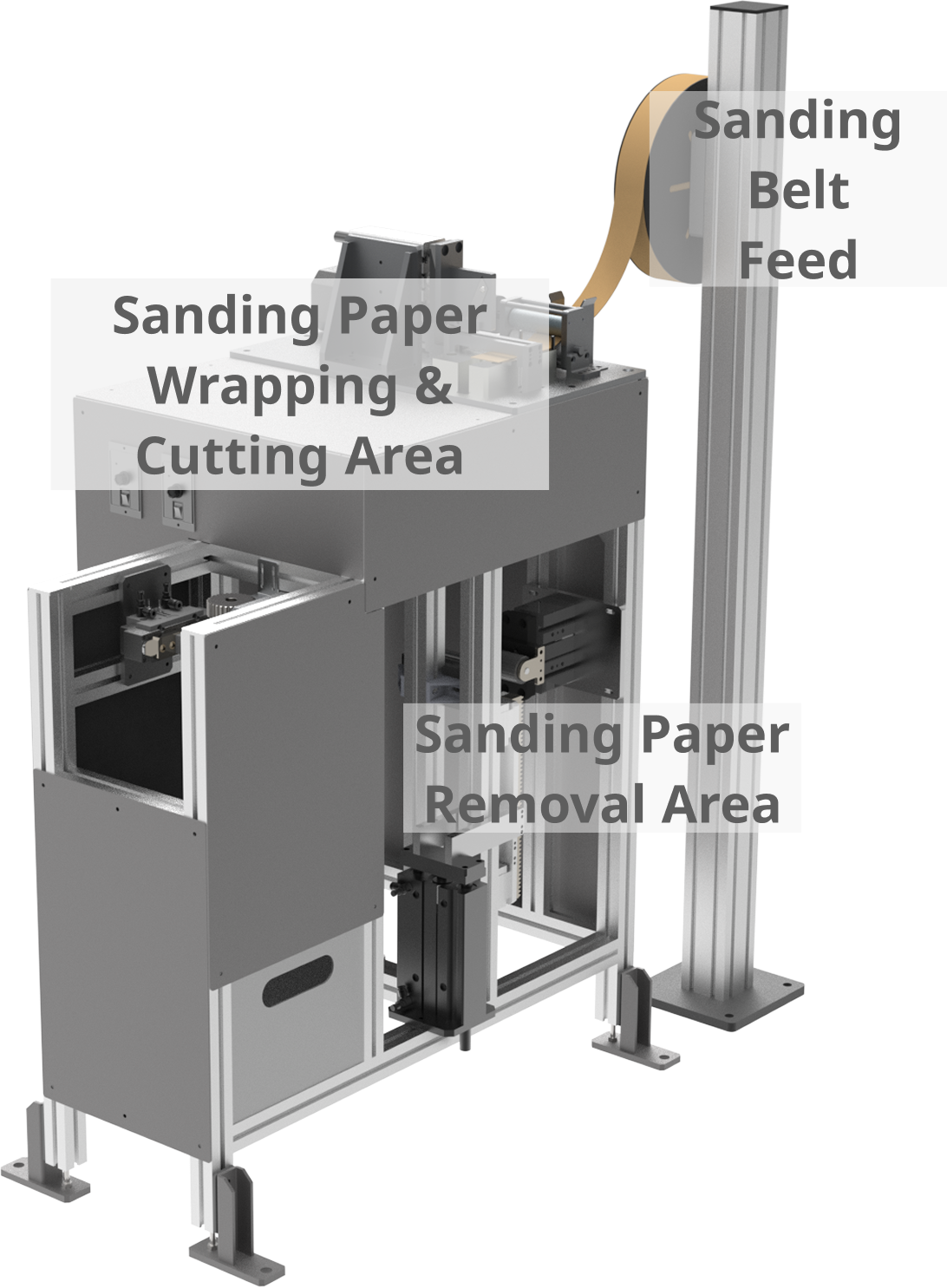

RCEdge300 is a pneumatic compliance force grinding tool featuring 360-degree radial compliance, specially designed for narrow corners and complex edges. It supports various abrasive papers, suitable for edge finishing and surface processing on diverse workpieces and materials. Equipped with an automatic sanding roll mechanism, it integrates with the DTroll-E1 system for automatic abrasive replacement, ensuring continuous and smooth robotic grinding even in hard-to-reach areas.

Grinding for Complex and Narrow Curved Surfaces

Aluminum, copper, steel, plastic, wood.

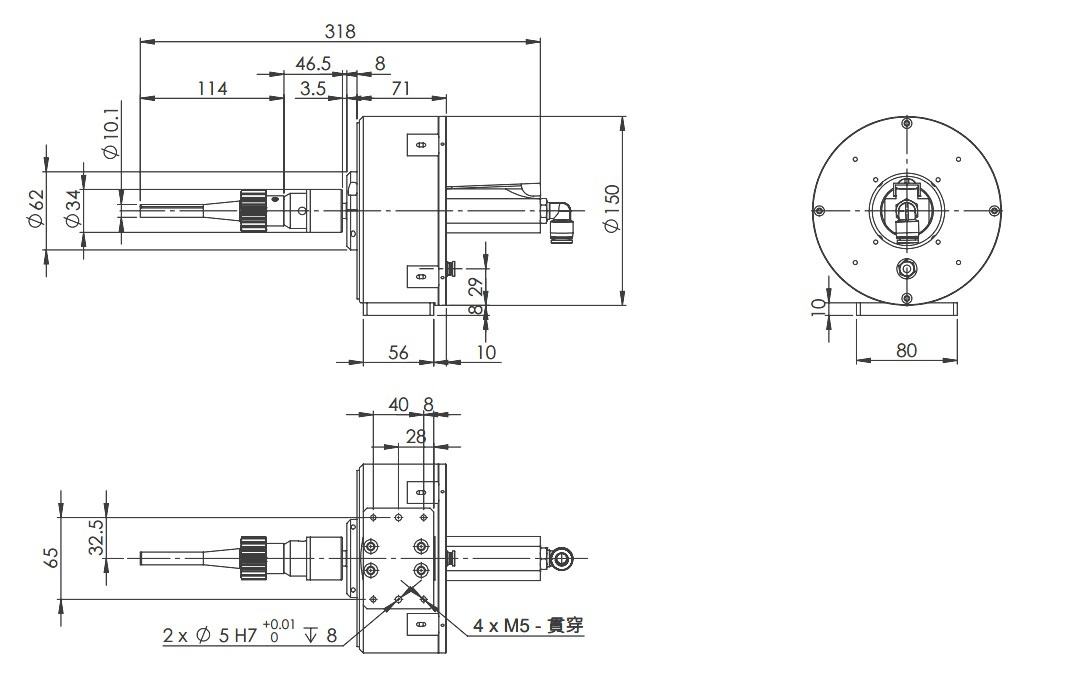

| Functions | Pneumatic Grinder |

| Collet Size | Ø10 |

| Compliant Pressure | 0.2-0.5 MPa (2-5 bar) |

| Compliant Stroke | Radial 3.5° |

| Compliant Force | 15-38N |

| Power | N/A |

| Spindle Pressure | 0.6 MPa (6 bar) |

| Weight | 4 kg (8.8 lb) |

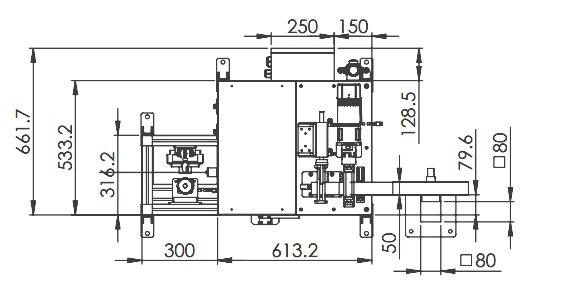

| Dimensions (L x W x H) | 350 x 150 x 158 mm (13.78 x 5.91 x 6.22 in) |

| Speed | 3200 RPM |

| Air Consumption | 450 LPM (L/min) |

Specifically designed for robotic applications to improve grinding coverage in narrow spaces and inner corners