In today's industrial sector, high-quality surface finishing has become an essential core requirement, covering metal processing, automotive manufacturing, aerospace, machinery manufacturing, defense industry, metal hardware, medical equipment, semiconductors, and 3C electronics among various industries. These industries have increasingly higher standards for surface quality, precision, appearance, and durability, making traditional manual processing unable to meet the stringent production demands. Therefore, integrating robotic automated surface finishing technology has become the key to enhancing manufacturing capabilities.

With the growing global emphasis on Environmental, Social, and Governance (ESG), the demand for robotic surface finishing systems is rapidly increasing, addressing the following four key challenges:

The shortage of skilled workers affects production line efficiency. Robotic systems provide stable productivity, reduce reliance on manual labor, and enhance product consistency and precision.

Traditional surface finishing involves dust, noise, and repetitive labor, posing health risks to workers. Robots can reduce human exposure to hazardous environments, improving occupational safety and meeting ESG social responsibility requirements.

Robotic surface finishing technology can enhance production efficiency and product durability, while precisely controlling material usage to reduce waste and lower energy consumption, meeting environmental sustainability goals.

Companies must comply with low-carbon emissions and energy-saving initiatives aligned with global trends. Robotic surface finishing systems effectively reduce production waste and improve resource utilization, enabling companies to achieve ESG goals while strengthening their competitive edge.

By adopting intelligent and automated surface finishing solutions, companies can not only tackle market challenges but also ensure high production efficiency, stable quality, and sustainable environmental development, comprehensively enhancing manufacturing competitiveness.

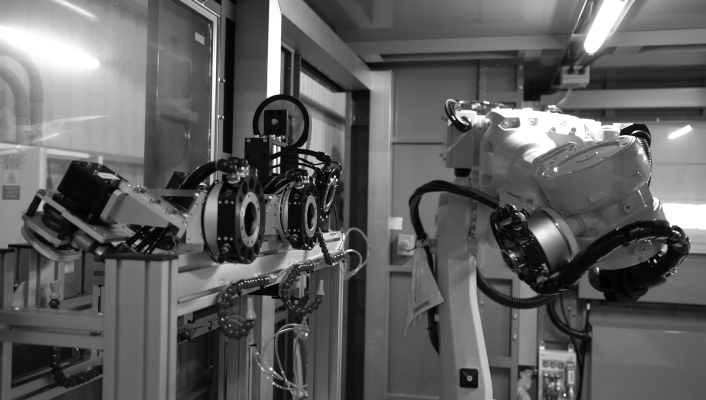

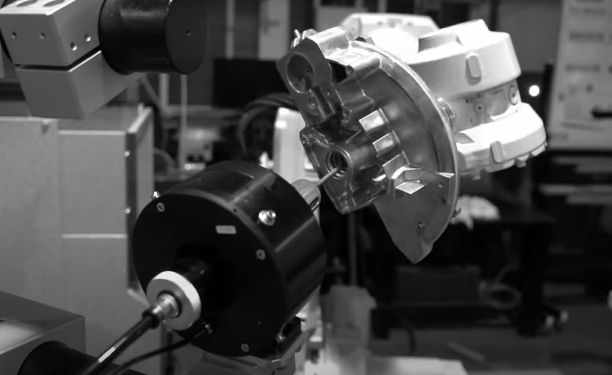

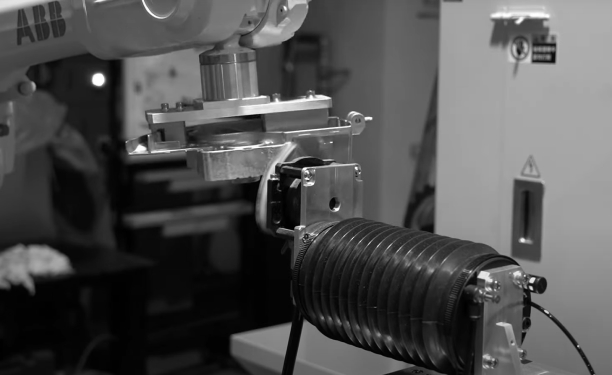

Providing stable, high-precision robotic grinding solutions for deburring, grinding, and polishing processes. Equipped with Compliance Force Control technology, ensuring consistent processing quality and flexibility. Adaptable to various workpiece shapes and material variations, reducing programming and operational complexity, enabling easy robotic automation implementation, and enhancing production efficiency and quality stability.

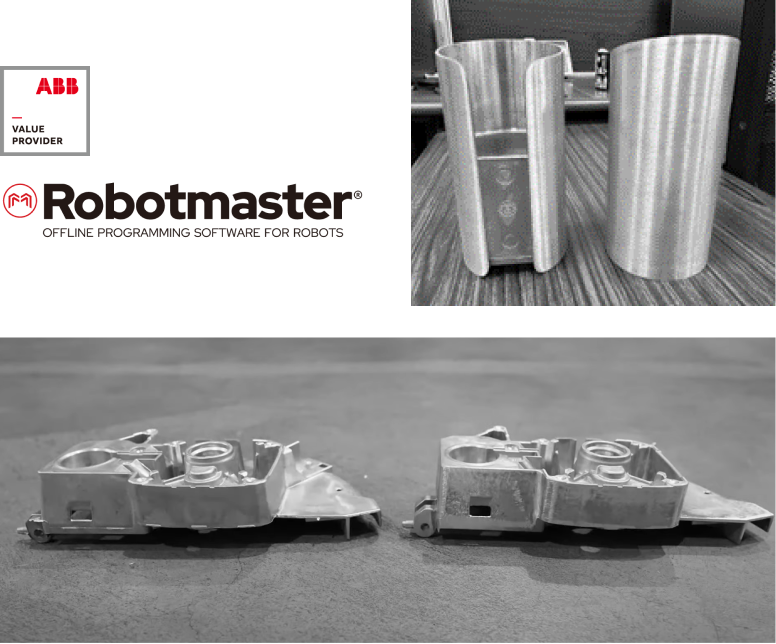

Robotmaster offline programming significantly simplifies robotic processing path setup, reducing programming time by over 70% while improving machining precision and production efficiency. DS automatic TCP calibration ensures perfect alignment between physical and virtual parameters, enhancing trajectory execution accuracy and guaranteeing consistency and stability in high-precision grinding applications.

As an officially authorized 3M distributor, we provide high-performance grinding materials specifically designed for robotic automation. 3M grinding consumables enhance processing efficiency, reduce replacement frequency, and ensure consistent surface quality, helping companies lower production costs, extend equipment lifespan, and achieve highly efficient automated manufacturing.

With over 11 years of expertise in robotic surface finishing, covering deburring, polishing, grinding, cutting, and sandblasting, we offer comprehensive automation solutions to help businesses enhance production efficiency, reduce costs, and ensure product consistency and high quality.

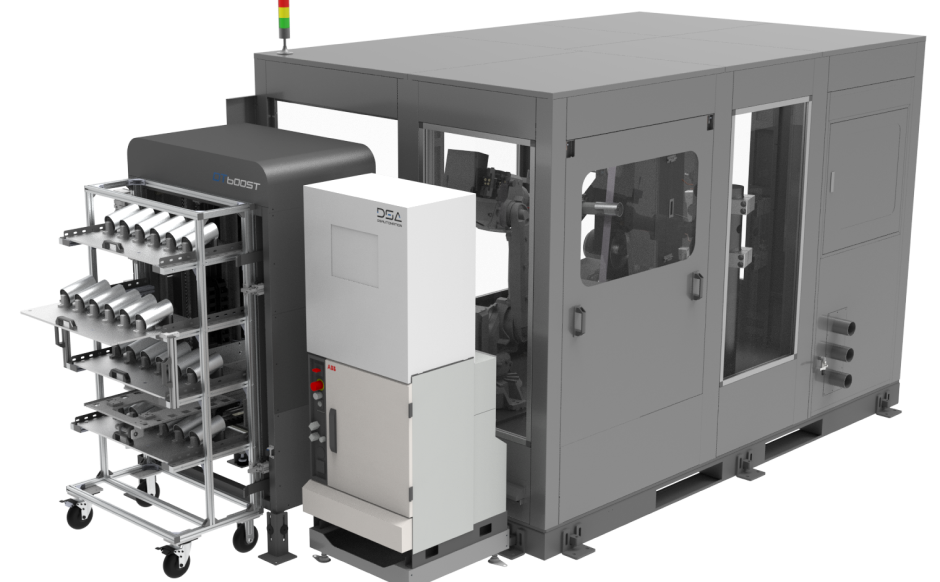

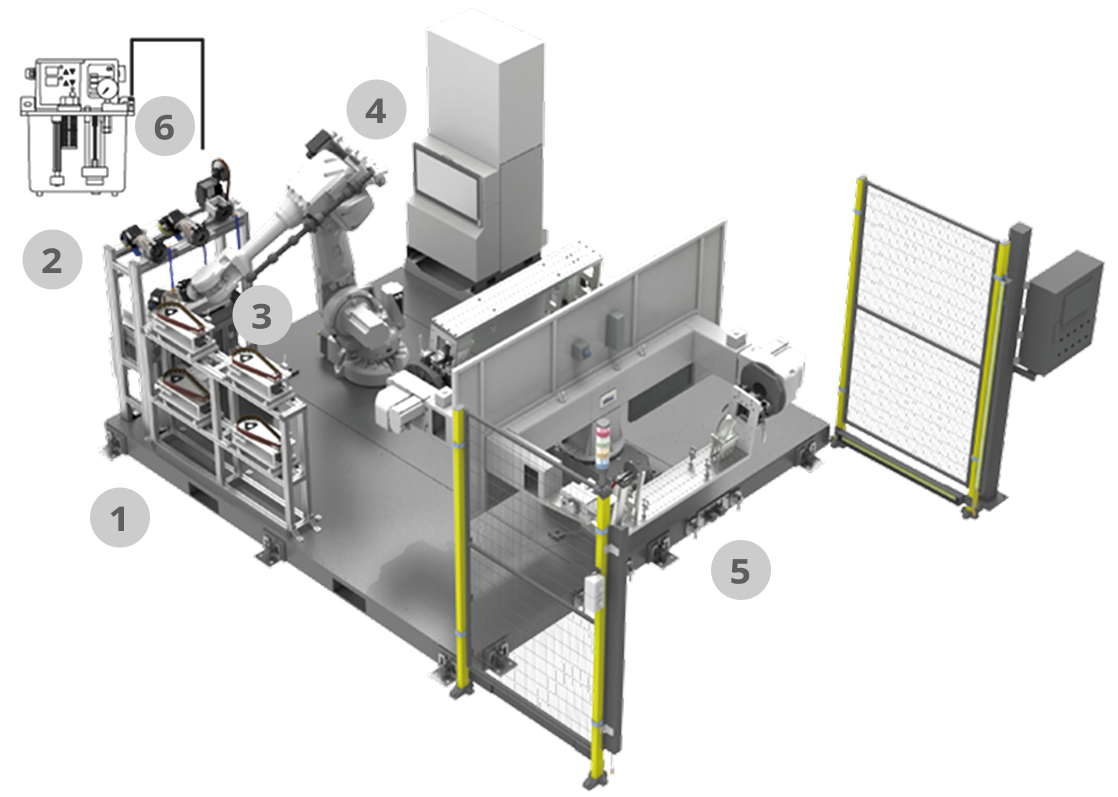

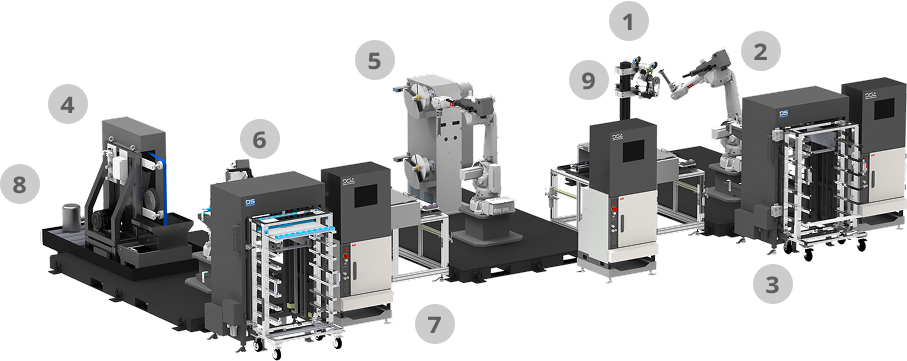

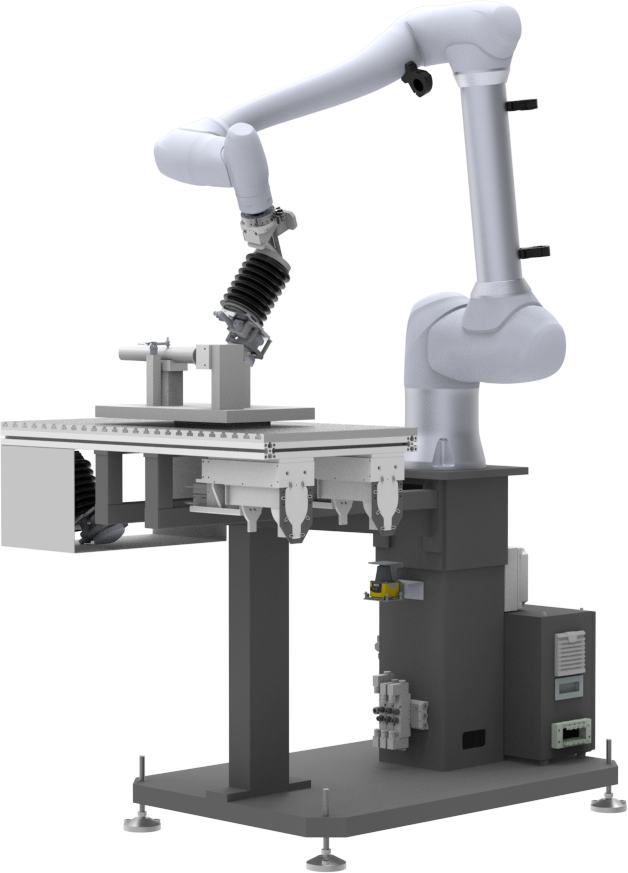

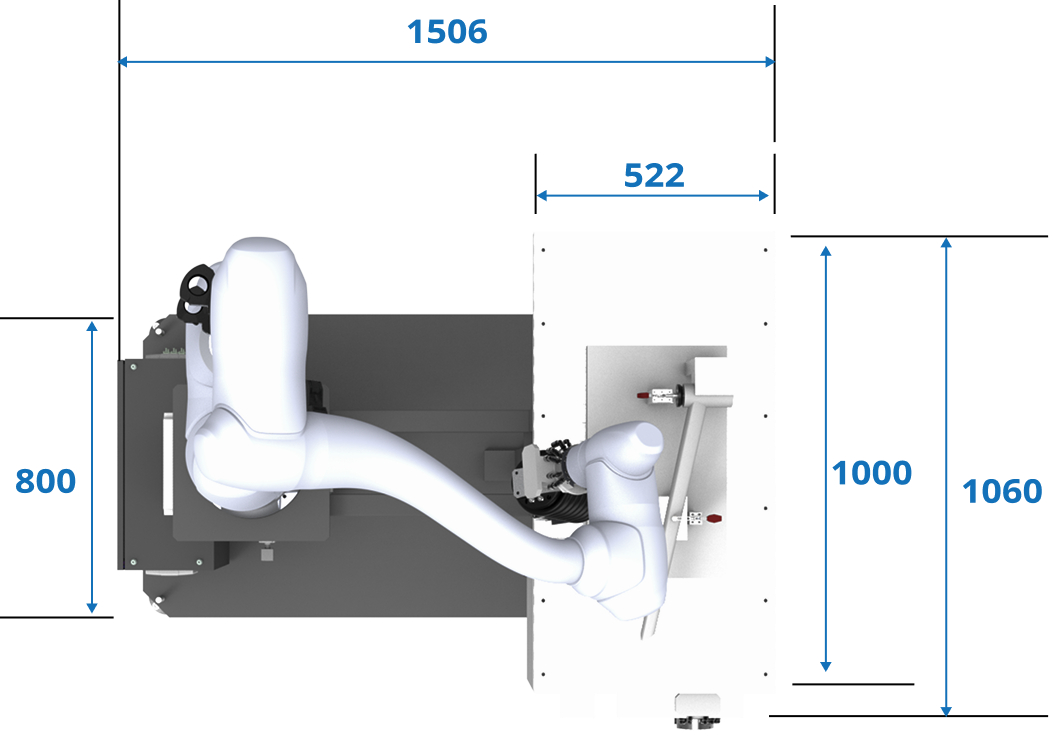

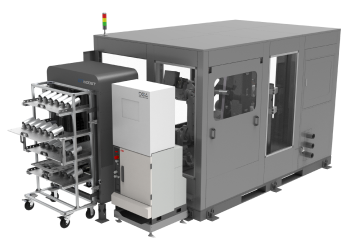

We offer two standardized robotic surface finishing systems to meet different workpiece sizes and application needs:

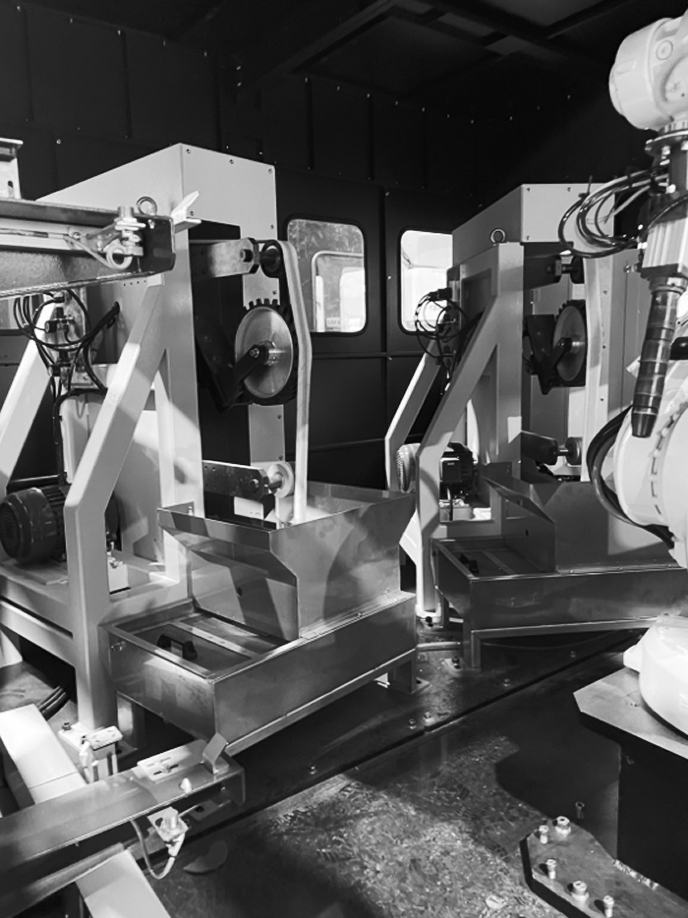

RTH-2TP Handheld Tool Type – Suitable for large workpieces, flexibly handling complex surfaces and detailed grinding

RWH-3DF Handheld Workpiece Type – Suitable for small workpieces, ideal for mass production, improving processing efficiency

These two modular systems feature high automation in surface finishing, making them ideal for aerospace, automotive, tool manufacturing, medical equipment, and metal processing industries. Their standardized design allows businesses to quickly deploy and flexibly configure the systems, easily adopting automation to significantly enhance production efficiency and quality stability.

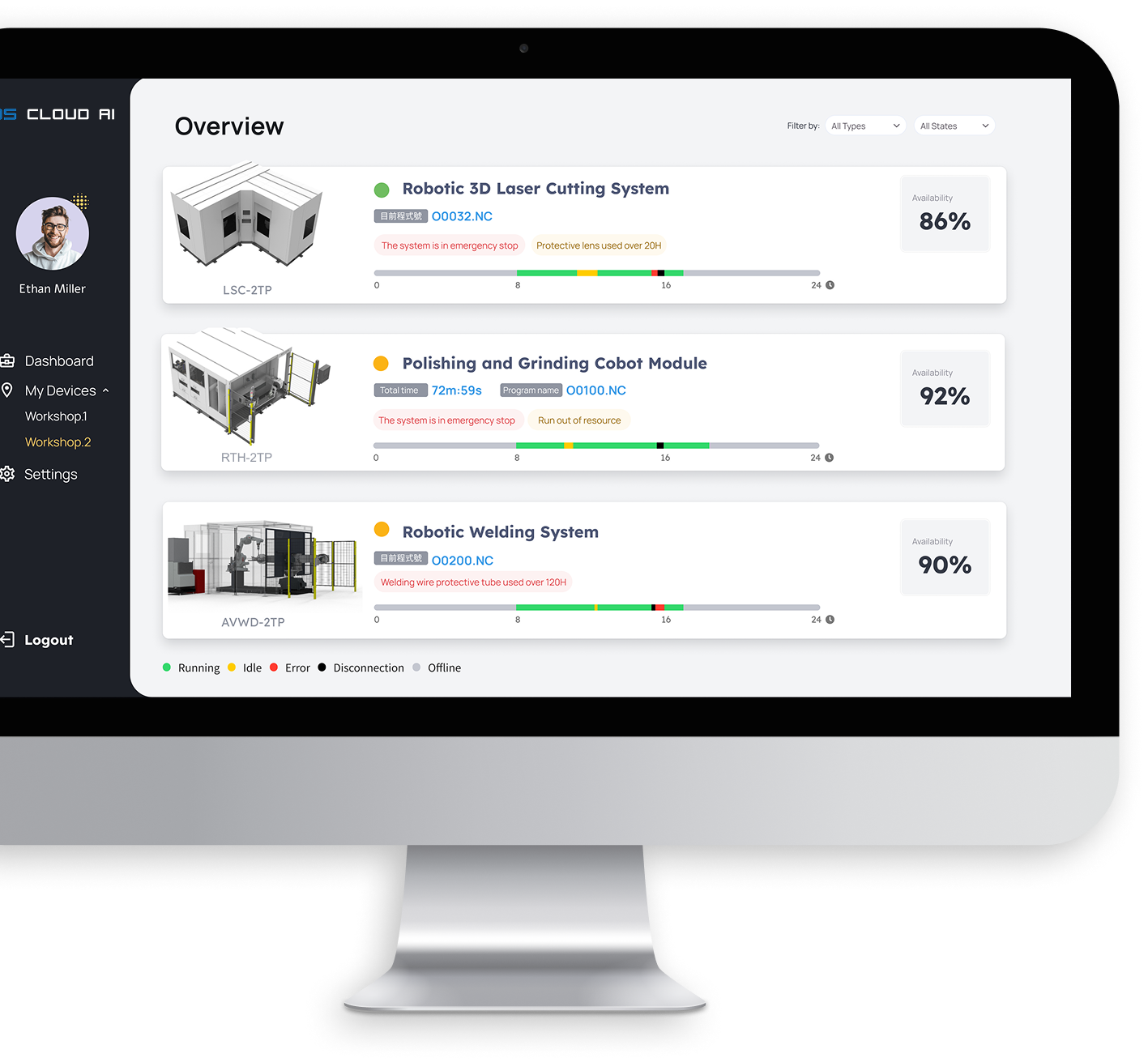

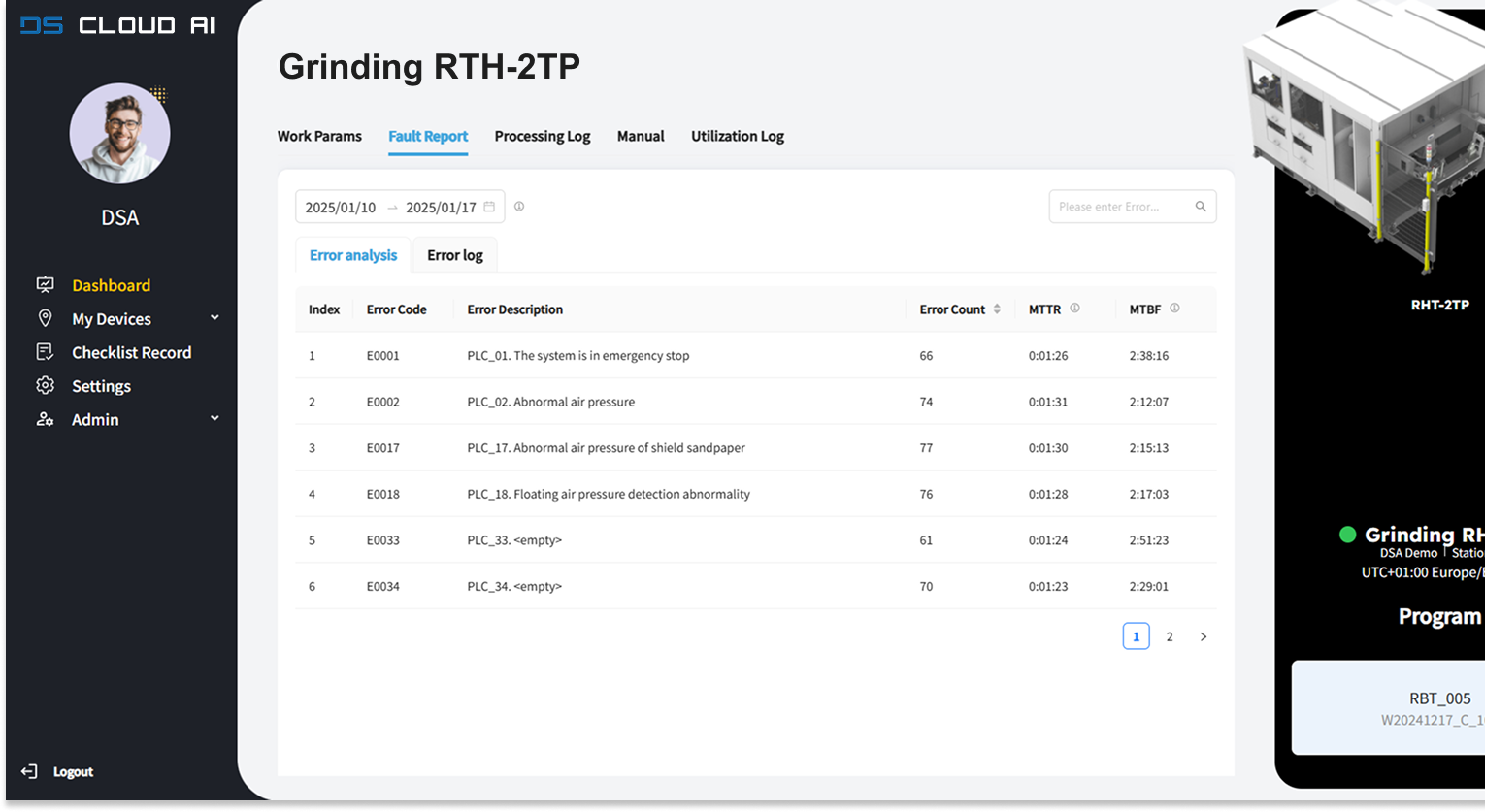

With AI-powered intelligent monitoring and data analysis, our system enables real-time equipment status tracking, failure risk analysis, and maintenance recommendations, reducing unplanned downtime and improving production line stability. Remote management and automated optimization of system parameters make manufacturing smarter, reduce manual dependency, and enhance overall production efficiency.

| Category | Robotic Automated Surface Finishing | Manual Surface Finishing |

| Production Efficiency | Operates 24/7 continuously, suitable for large-scale standardized production | Suitable for small-batch, diverse products, but efficiency is limited |

| Processing Precision | Compliance Force Control technology ensures stable processing, improving consistency and quality | Relies on worker experience, suitable for fine detail work but lacks consistency |

| Standardization & Reproducibility | Automation ensures consistent quality and reduces errors | Manual operation varies, making stable quality difficult to ensure |

| Adaptability to Different Shapes & Materials | Utilizes TCP calibration + Robotmaster offline programming, adaptable to most regular-shaped workpieces, but manual finishing is still required for small intricate areas | Flexible in handling complex surfaces and fine details, suitable for specialized workpieces |

| Suitability for Small-Batch, High-Mix Production | Ideal for standardized workpieces with medium-to-high production volume but requires longer implementation time | Best for small-batch, high-mix manufacturing with no need for programming adjustments |

| Labor Demand | Reduces dependence on skilled workers by over 70%, though manual finishing is still needed | Fully relies on skilled workers, leading to high training and management costs |

| Work Environment & Safety | Reduces exposure to dust, noise, and repetitive labor, improving occupational health | Workers are exposed to dust and noise for extended periods, posing significant health risks |

| Flexibility & Adaptability | Best suited for large-scale standardized production, though some details still require manual intervention | Highly flexible for different products, but processing time is longer |

| Maintenance & Operational Stability | AI predictive maintenance (DS Cloud AI) reduces unplanned downtime and enhances stability | Manual monitoring is required, as wear and tear cannot be detected in real-time |

| Cost-Effectiveness | Reduces long-term labor and material costs, though initial investment is high | Lower initial investment but higher labor and management costs |

| Environmental & ESG Compliance | Reduces energy consumption, material waste, and carbon emissions | Higher material waste with limited environmental control |

| Application Scenarios | Ideal for metal processing, automotive, aerospace, tool manufacturing, and medical equipment industries | Best suited for manual fine finishing and specialized product manufacturing |

Robotic automated surface finishing ≠ Replacing manual work, but rather improving standardization and production efficiency. Companies should consider production volume, product characteristics, labor, and cost factors to determine the optimal grinding method, and may adopt a hybrid model combining automation with manual finishing to achieve maximum efficiency and quality.

Based on different application requirements, we provide four types of robotic surface finishing systems, covering standard modular systems and customized solutions to ensure customers can choose the most suitable automated surface finishing solution, enhancing processing efficiency and quality stability.

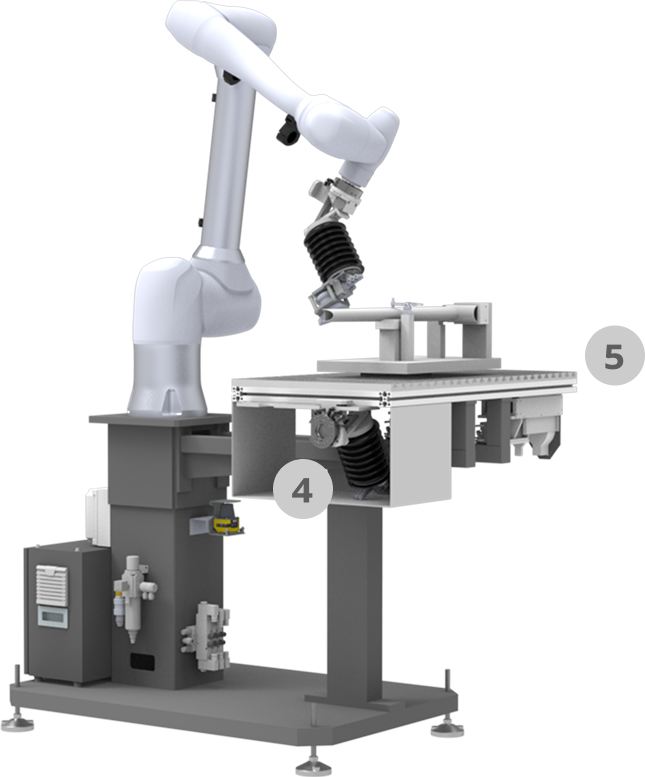

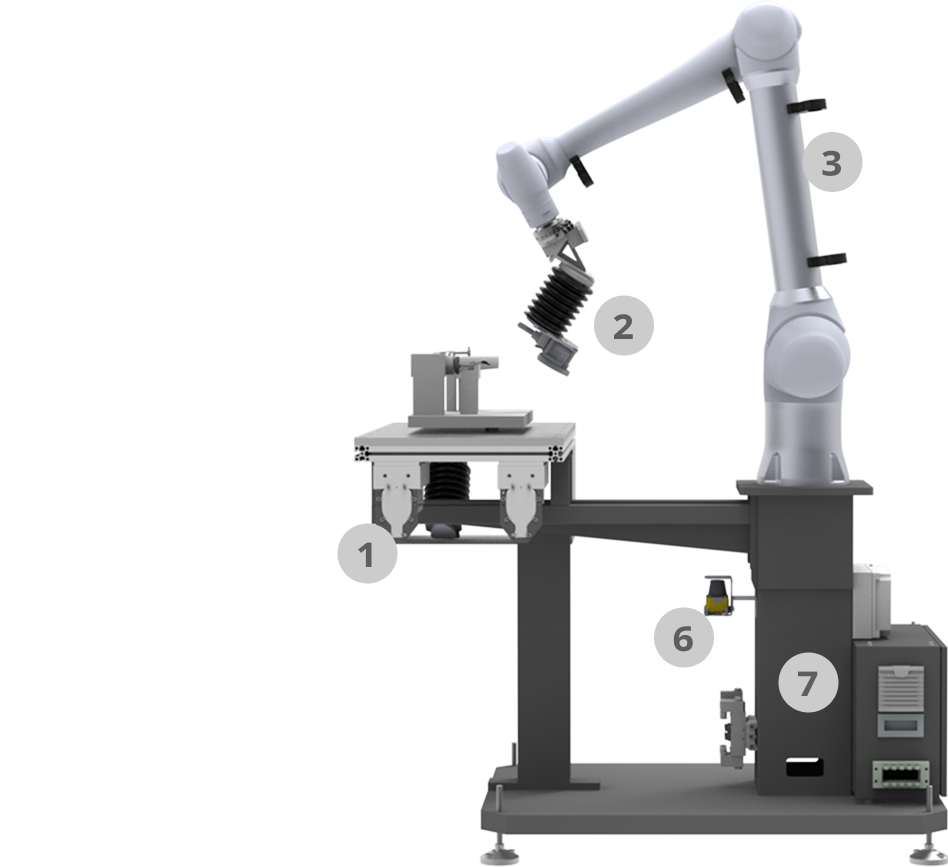

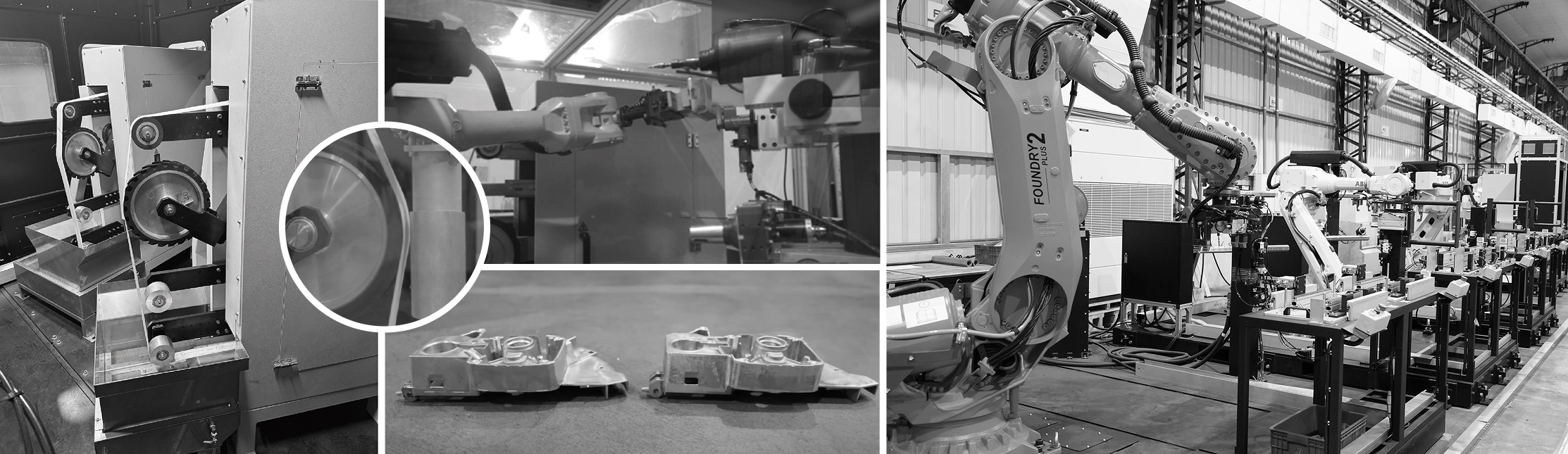

We offer three standardized modular systems suitable for different types of workpieces and processing requirements:

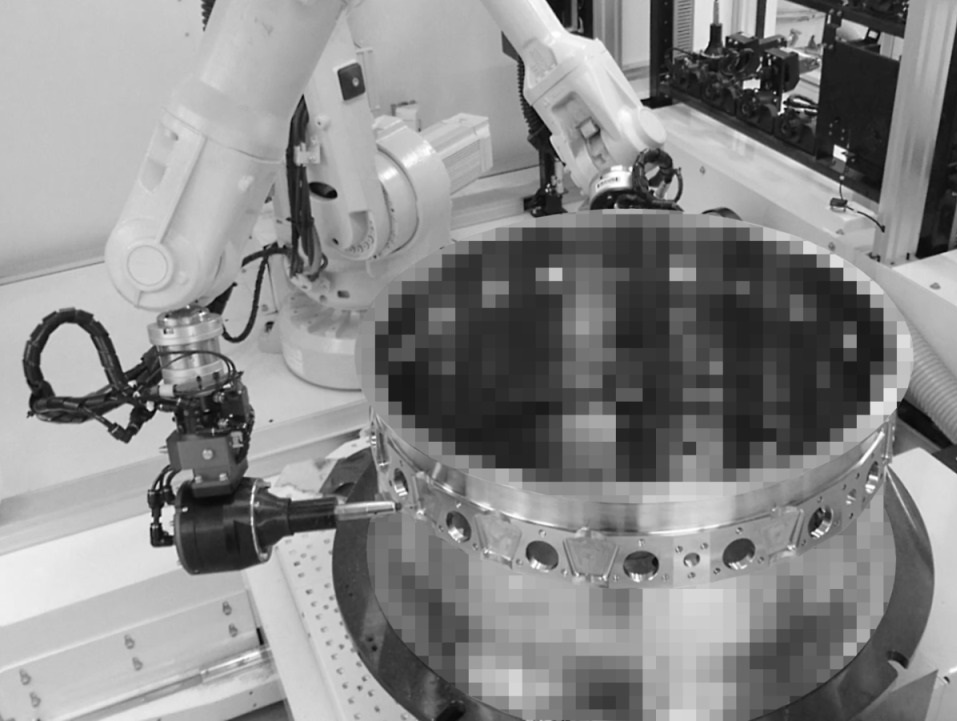

Suitable for large workpieces, utilizing a robot to hold surface finishing tools for deburring, grinding, and polishing . The dual-station design improves processing efficiency and reduces robot idle time, making it ideal for applications requiring high coverage treatment, such as post-welding surface finishing and large-area deburring.

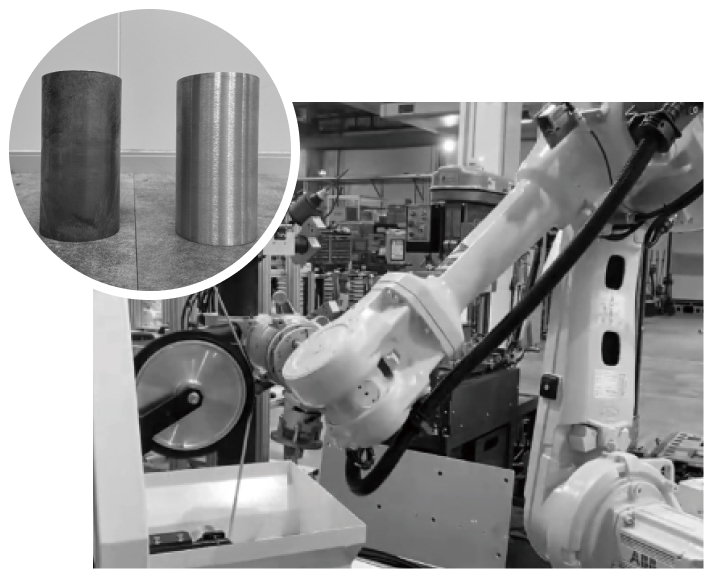

Designed for small to medium-sized workpieces, where the robot clamps and secures the workpiece for deburring, grinding, and polishing, ensuring stability and consistency. Suitable for mass production and high-precision surface finishing applications, such as medical devices, 3C products, and high-end metal component manufacturing.

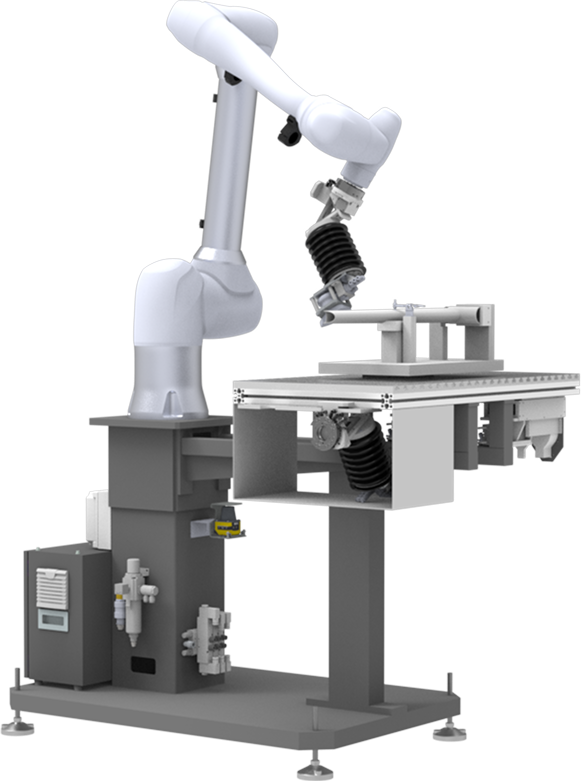

Ideal for small workstations and flexible application scenarios, the collaborative robot can coexist with human operations, lowering the automation barrier. It is suitable for fine surface finishing and specialized small parts deburring, grinding, and polishing, making it particularly beneficial for companies in the early stages of automation or production lines requiring high flexibility.

For specialized workpieces or high-end application scenarios, we provide highly customized surface finishing solutions. The RSFinC system can be tailored to customer needs, adjusting workpiece clamping methods, surface finishing tools, processing paths, and intelligent control systems to ensure optimal processing efficiency and surface quality. It is suitable for industries with high requirements, such as aerospace, medical, and precision component manufacturing.

After weld seam grinding, the pipe surface roughness is processed simultaneously to ensure a uniform and consistent surface quality. Upon measurement, the surface roughness (Ra) can reach 1.3, making it suitable for direct liquid coating application, enhancing the final product's appearance and durability.

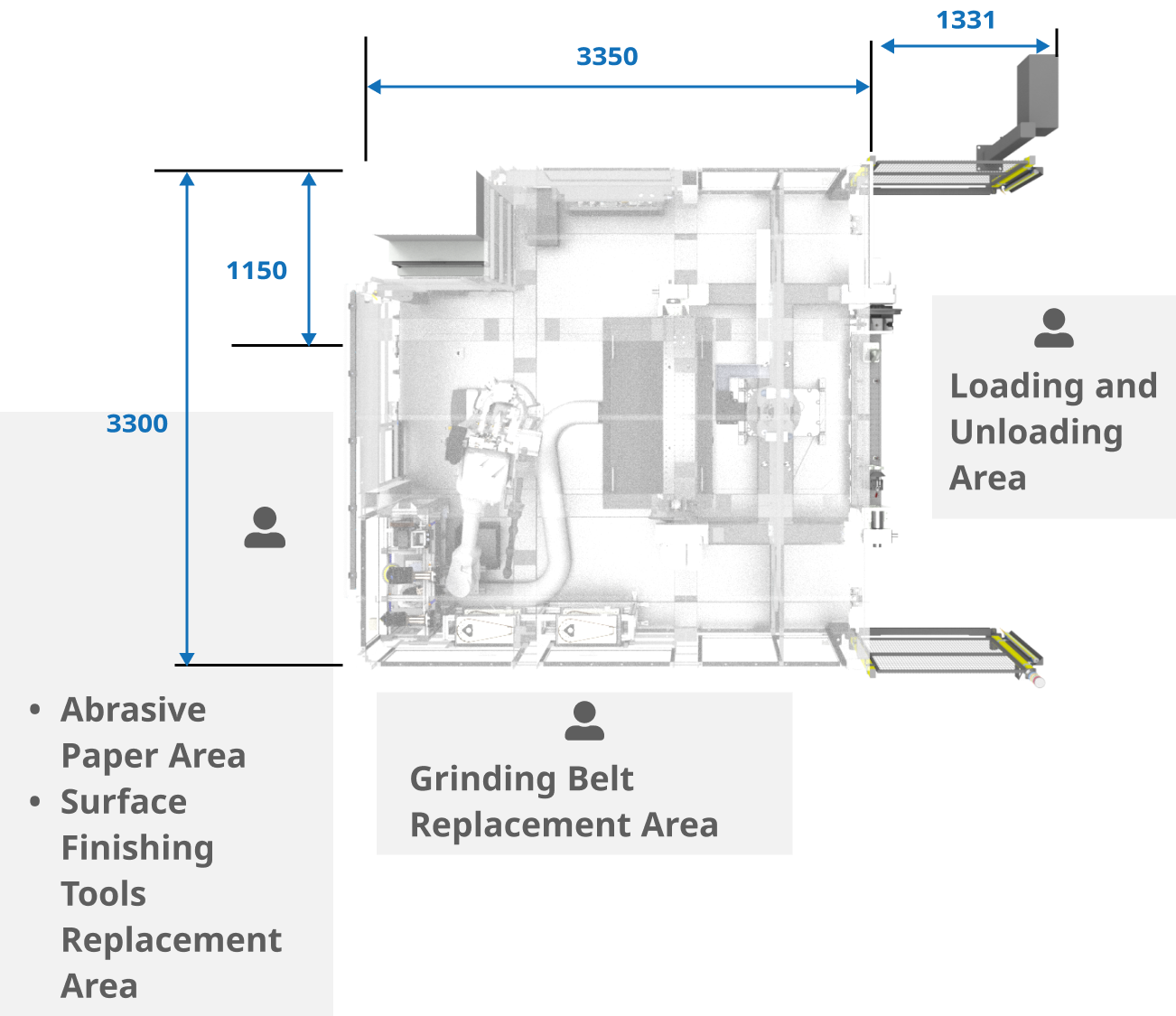

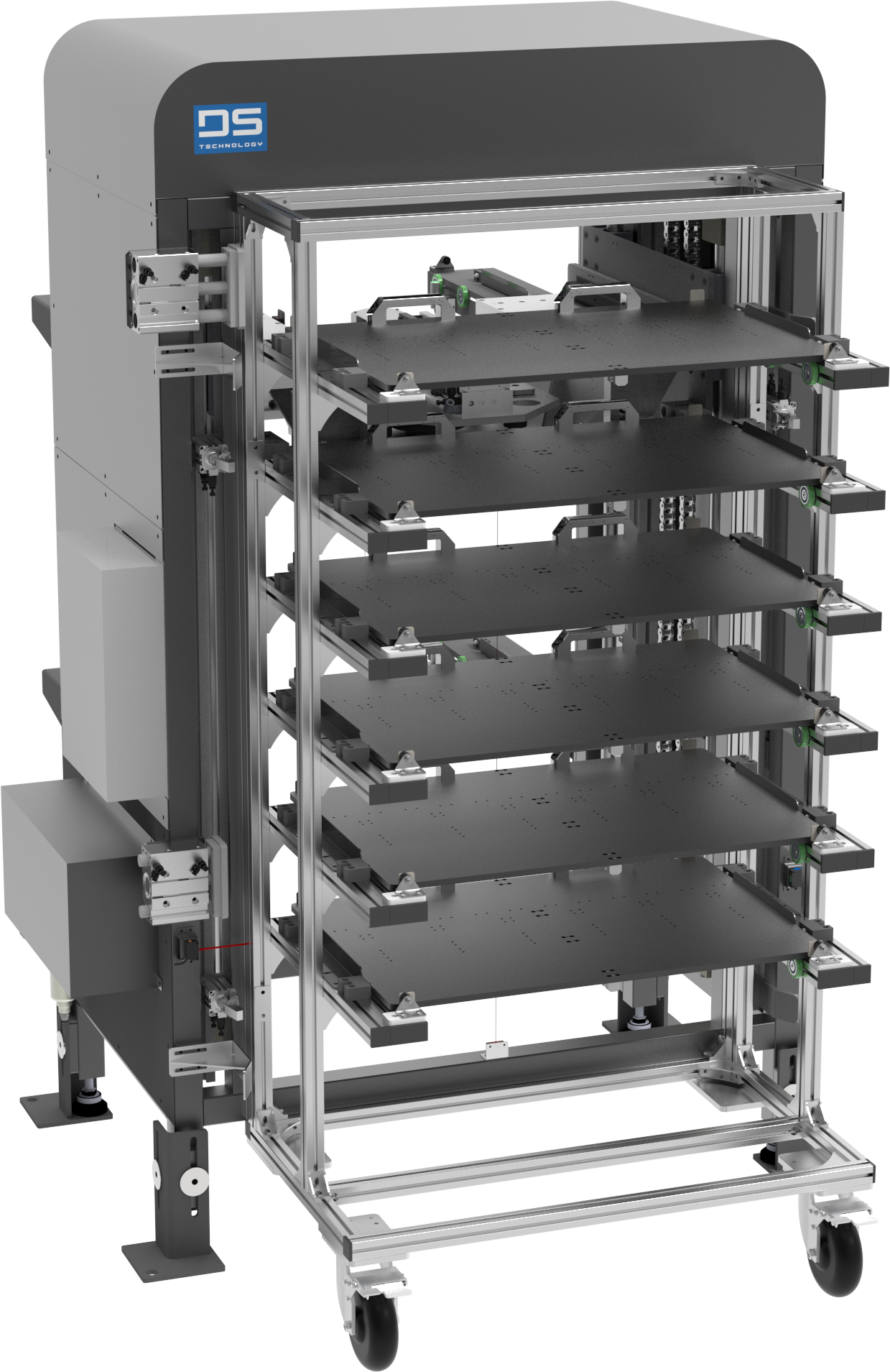

The 3D automated loading system enables stacking up to 5-6 layers based on workpiece size, maximizing vertical space and reducing system footprint.

The trolley allows fast batch transfers and smooth workpiece transitions, reducing manual effort and improving efficiency.

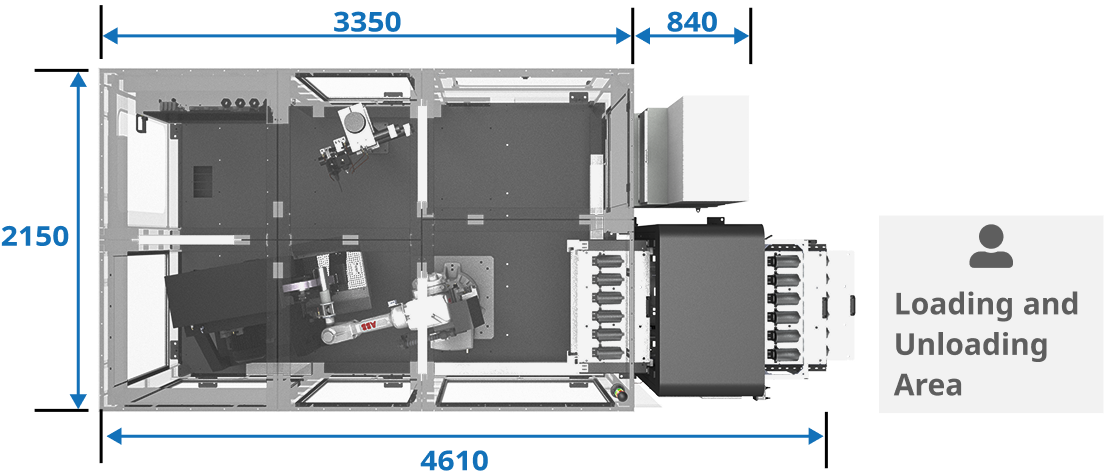

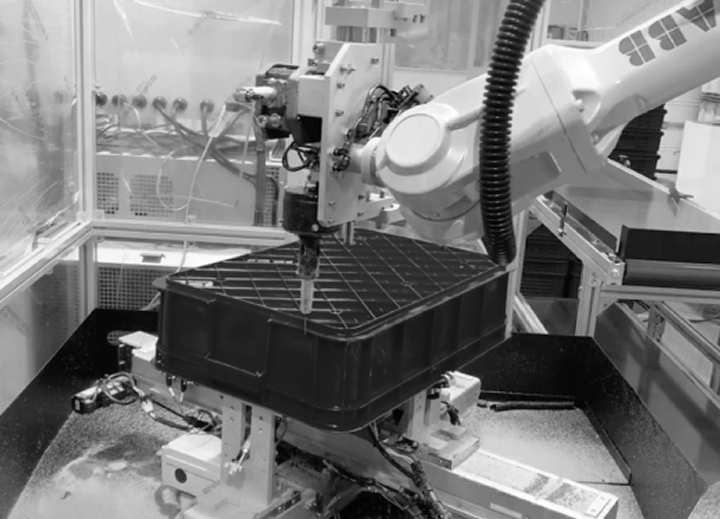

This equipment is a surface finishing platform designed for large workpieces. It precisely processes the peripheral structures and bases of semiconductor equipment and is widely used in aerospace, aviation, yachts, and ship surface finishings.

Equipped with the full range of DS FlexRC tools, it meets various surface finishing needs, including grinding, polishing, and deburring. In continuous automated production environments, an optional automatic sandpaper replacement system enables seamless, continuous production, improving efficiency and ensuring stable surface quality. RSFinC not only enhances processing precision but also significantly reduces manual intervention, making production more consistent and reliable while meeting stringent surface finishing standards across industries.

Although modern injection molds have minimized burr formation, large injection-molded parts such as baskets, pallets, and automotive components still inevitably have burrs and residual runners. Manual deburring for large workpieces is inefficient and places a significant physical strain on workers.

The DS FlexRC tool enables robots to easily replace manual labor, reducing barriers to industrial upgrading and transformation.

Mass-produced machined components require extensive deburring work, with higher appearance standards compared to cast parts.

By integrating robotic automation with DS FlexRC tools, a lower-cost solution can achieve superior results.

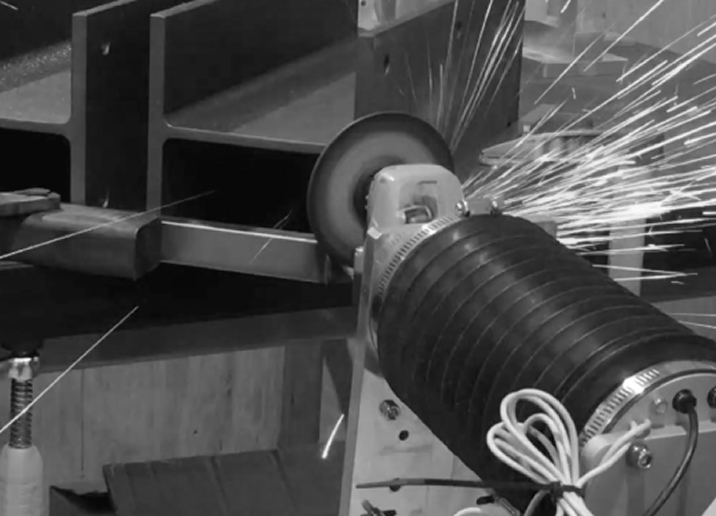

With the widespread adoption of robotic welding, weld seam grinding has become a bottleneck in the production process. The challenge of automation has been the inability to remove weld seams precisely without damaging the base material.

The DS FlexRC tool features a floating mechanism that controls grinding force and detects sheet metal height, ensuring perfect weld seam removal.

Aluminum die-casting has short production cycles and high output, making deburring a common bottleneck suitable for automation.

The DS FlexRC tool offers multiple floating mechanisms and grinding heads, adapting to complex shapes for precise deburring and surface grinding. It enhances quality and efficiency while leveraging automation to increase grinding rates and reduce production costs.

DS FlexRC provides various belt sanders and flap wheel configurations to flexibly meet diverse surface finishing needs.

By integrating with DS FlexRC tools, automated grinding rates and efficiency can be significantly improved while lowering production costs.

with Compliant Force Technology

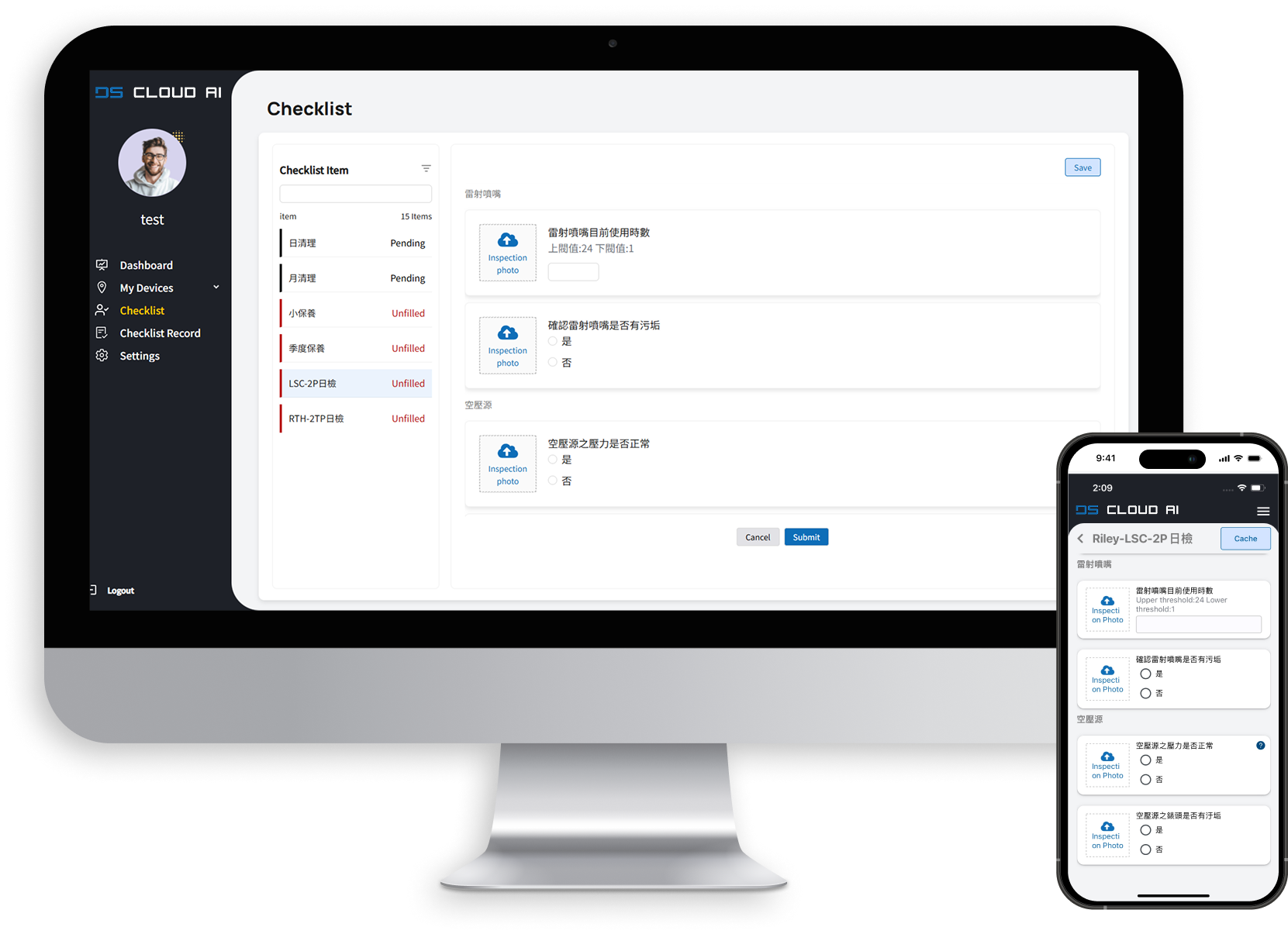

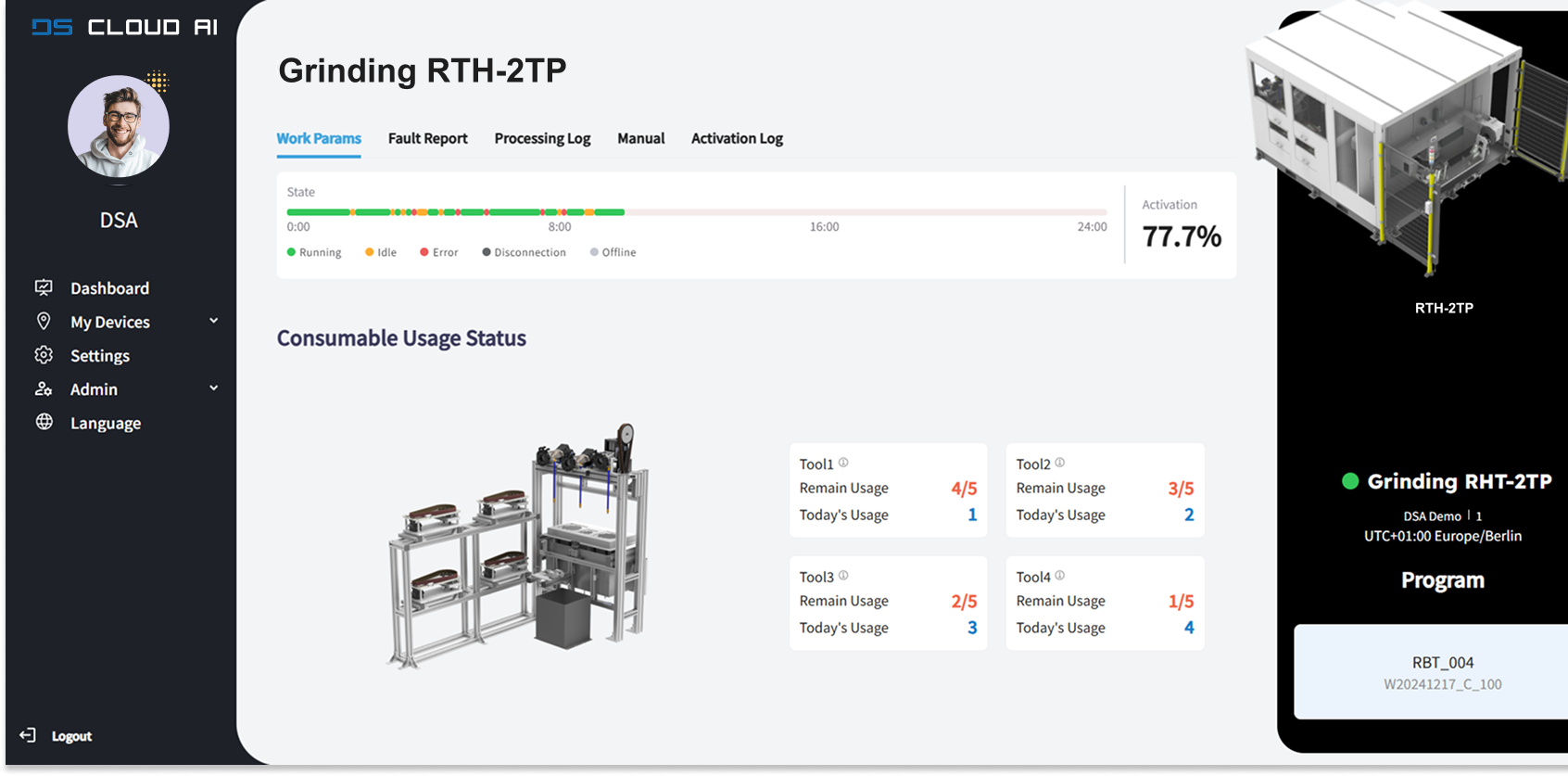

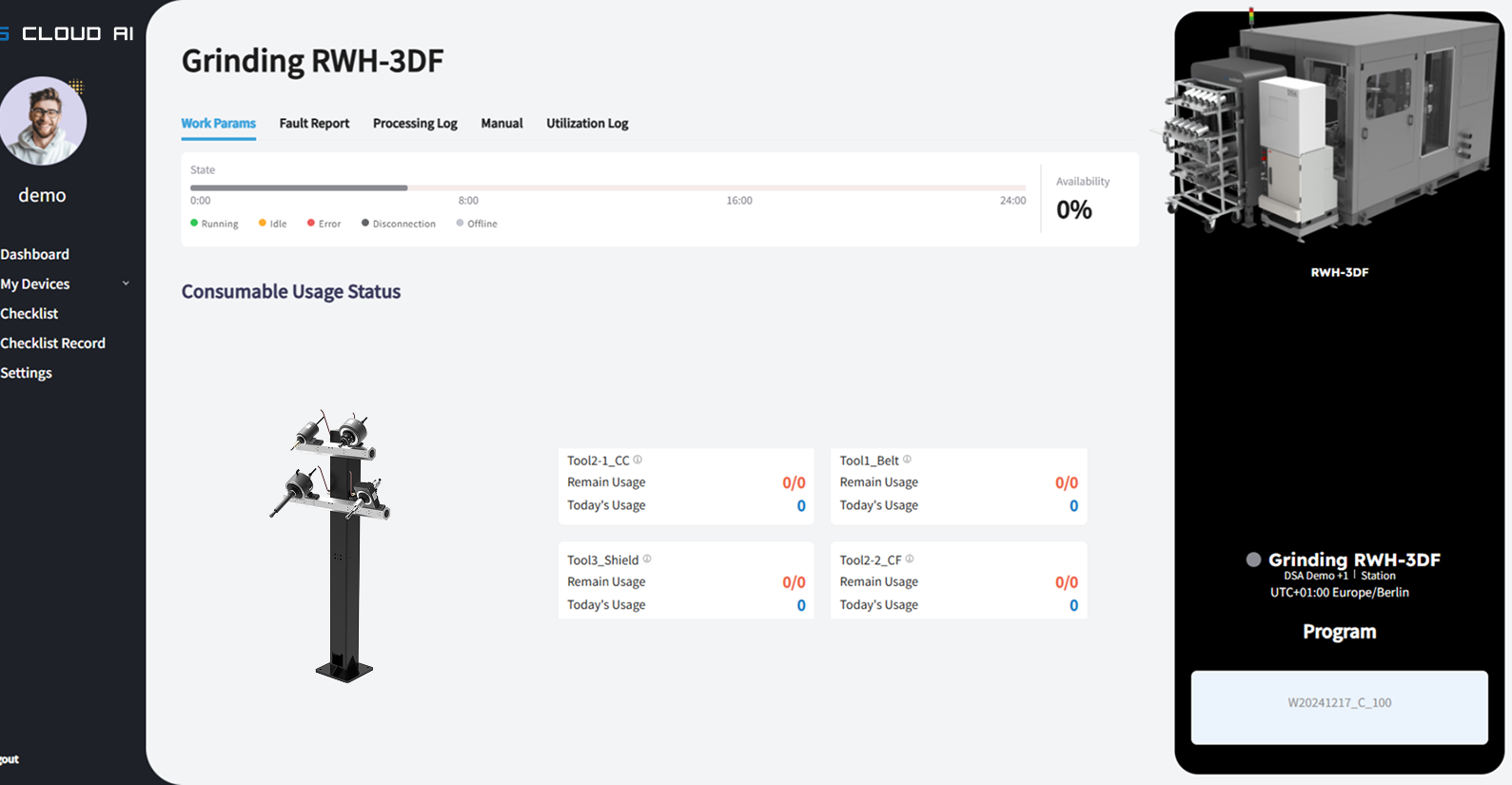

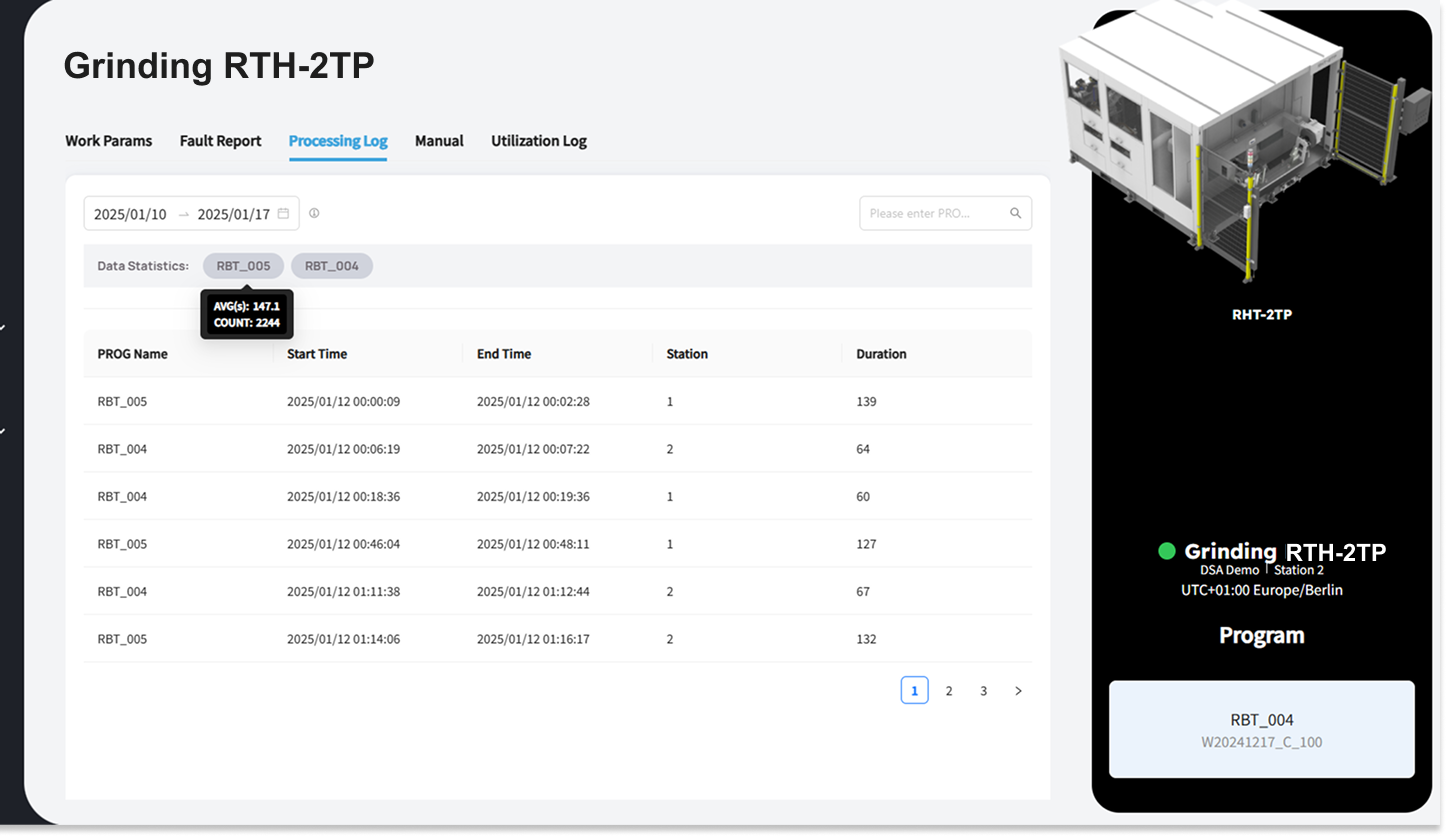

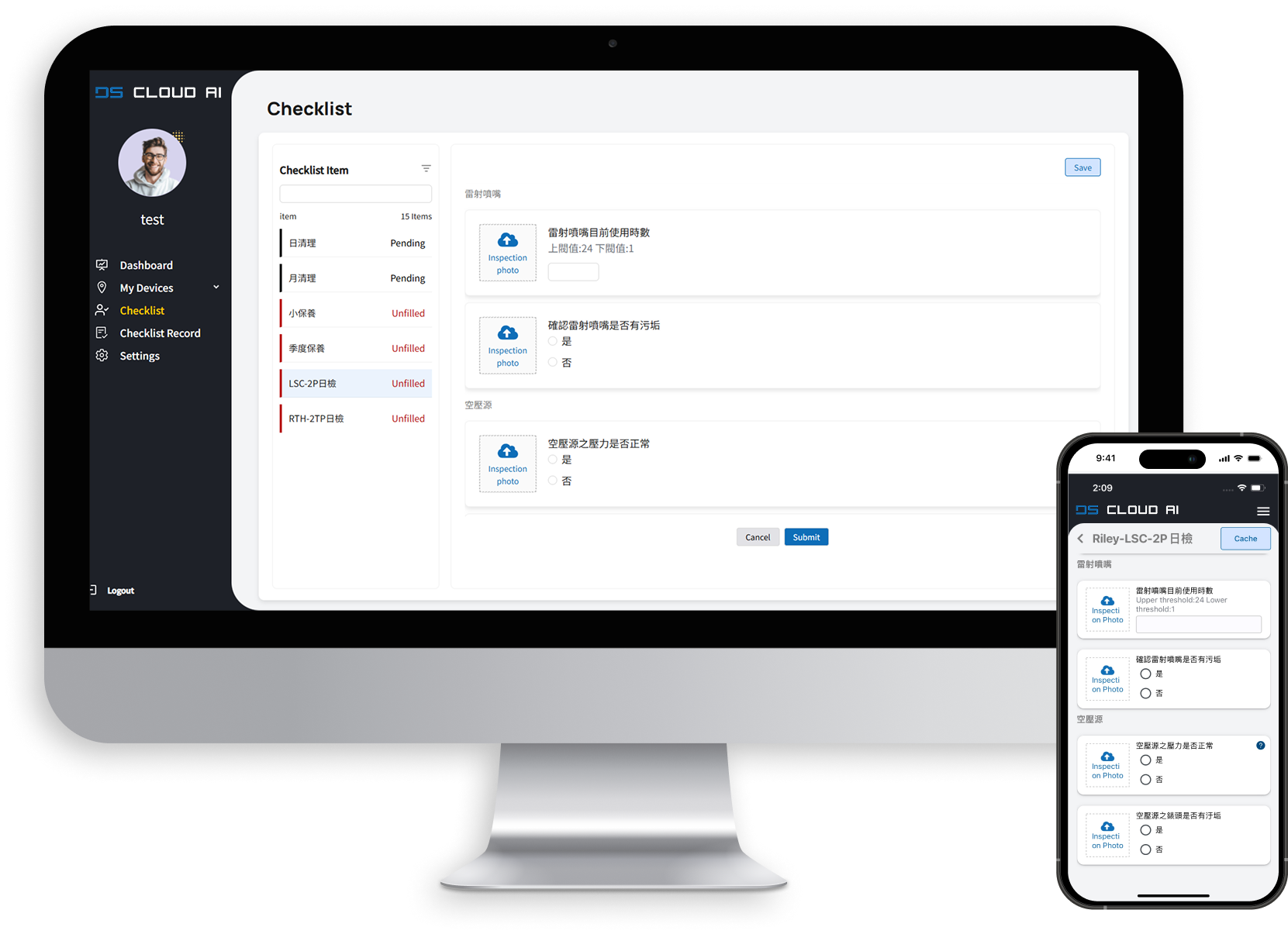

Connect your DSA/DS Technology devices to the internet and manage them effortlessly with DS Cloud AI.

DS Cloud AI allows you to monitor equipment status anytime and use AI intelligence to quickly resolve issues, ensuring stable and efficient operations.

*Consumable usage statistics method: Measure units are defined according to the consumable properties, typically by time or count.

With utilization rate records, you can analyze equipment or system usage, optimize performance, and effectively manage resources to enhance production efficiency, reduce downtime, and achieve optimal resource allocation.

This system allows you to record and review inspection results, helping to identify and resolve equipment issues, ensuring timely maintenance and improved performance.

Robotic surface finishing systems help businesses comply with global environmental regulations, including the U.S. Clean Air Act, the EU Air Quality Directive, the China Air Pollution Prevention and Control Law, and environmental standards across Southeast Asia. These systems enhance resource efficiency, reduce energy consumption and pollutant emissions, ensuring environmental compliance in global markets and promoting sustainable development.

Through precise control of grinding and polishing processes, these systems effectively minimize material waste, improve resource utilization, lower production costs and reduce waste disposal burdens, aligning with global efficient resource management policies.

Automated grinding systems are equipped with optimized energy management technologies, reducing energy waste in compliance with ISO 50001 energy management standards and global energy-saving and carbon reduction regulations, This helps businesses achieve higher energy efficiency and may qualify them for subsidies or tax incentives.

Advanced dust and wastewater treatment technologies effectively control pollutant emissions during production, ensuring compliance with industrial emission standards worldwide, such as the U.S. Clean Water Act and the EU Industrial Emissions Directive. This not only reduces the risk of environmental fines but also enhances a company's ESG performance and strengthens market competitiveness.

Automated grinding systems help businesses comply with global occupational safety and health regulations, such as the U.S. OSHA Occupational Safety and Health Act, the EU Workplace Safety and Health Directive, China’s Occupational Safety and Health Law, India’s Worker Safety and Health Act, and safety standards across Southeast Asia. These systems reduce the risk of workplace injuries and ensure a safe working environment.

Robotic grinding systems are equipped with safety protection mechanisms and emergency stop functions, ensuring compliance with equipment safety standards. By reducing the need for direct human involvement in high-risk tasks, these systems help lower workplace injury rates, improve employee job satisfaction, and enhance productivity.

Through high-efficiency dust collection and filtration systems, these systems significantly reduce dust concentration, ensuring compliance with ISO 45001 occupational health and safety standards. This effectively protects employees’ health and minimizes the risk of occupational diseases caused by long-term exposure to hazardous environments.

Automated grinding systems not only improve working conditions and reduce health risks for employees but also help businesses comply with global corporate social responsibility (CSR) standards, demonstrating their commitment to environmental sustainability and employee well-being.

These systems comply with ISO 45001 (Occupational Health and Safety Management) and ISO 14001 (Environmental Management Systems), as well as global occupational safety and environmental management standards, ensuring compliance in the U.S., EU, Japan, China, India, and Southeast Asian markets. This highlights the company's dedication to global safety and environmental responsibility.

The DS Technology robotic surface finishing system integrates deburring, grinding, and polishing core technologies and features compliant force control, AI intelligent monitoring, automatic TCP calibration, and Robotmaster offline programming, providing a high-precision, high-efficiency automated surface finishing solution. Our modular and customizable system is suitable for industries such as aerospace, automotive, machinery, metal processing, and 3C electronics, meeting diverse needs from small-batch precision processing to large-scale automated production.

By choosing DS Technology, you will gain:

DS Technology has a comprehensive global distributor and technical support network covering Asia, Europe, Americas and other major markets.

Service Locations

Service Locations

Distributors

Distributors

ODM Partner

ODM Partner