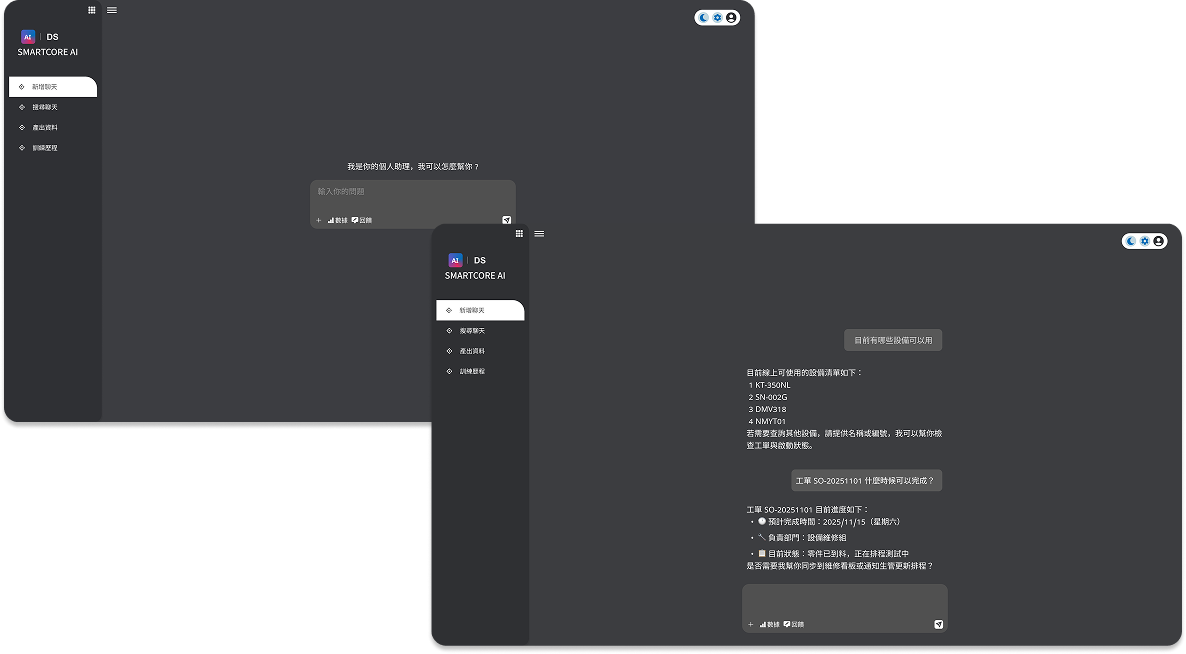

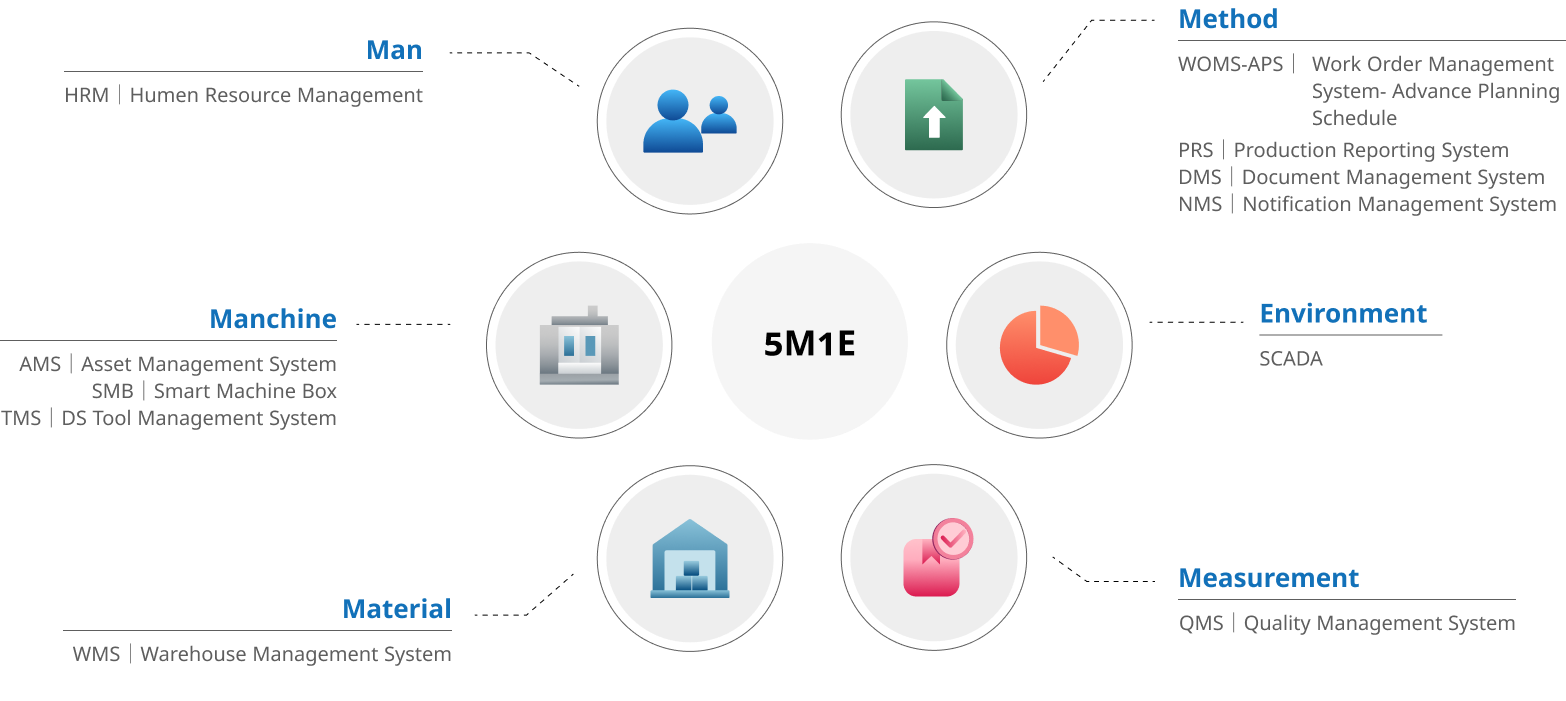

DS MES is based on the 'Personnel, Machine, Material, Method, Environment, Measurement' framework, integrating human resources, equipment, materials, processes, quality, and environment information, and linking to DS SmartCore AI. The system connects modules in real time and supports scheduling checks, process monitoring, quality traceability, and intelligent decision-making to build an efficient, traceable, and controllable smart manufacturing system.

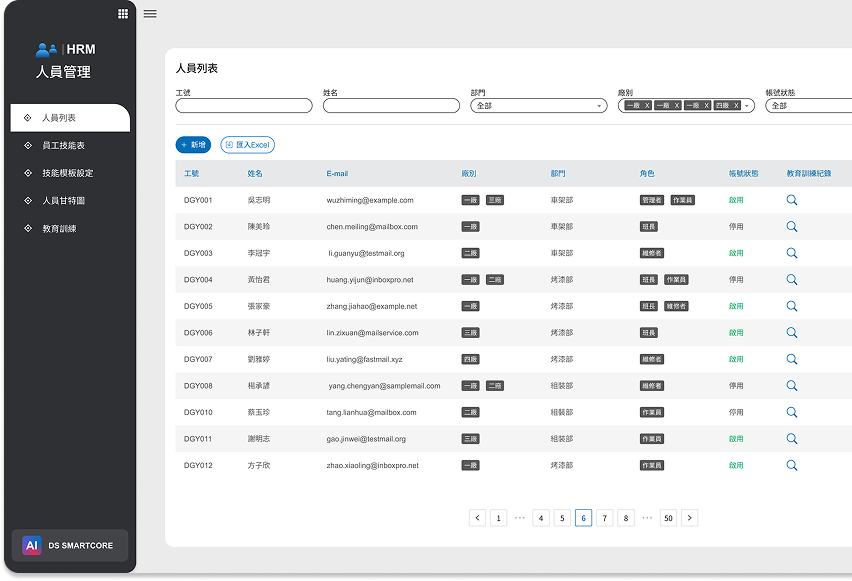

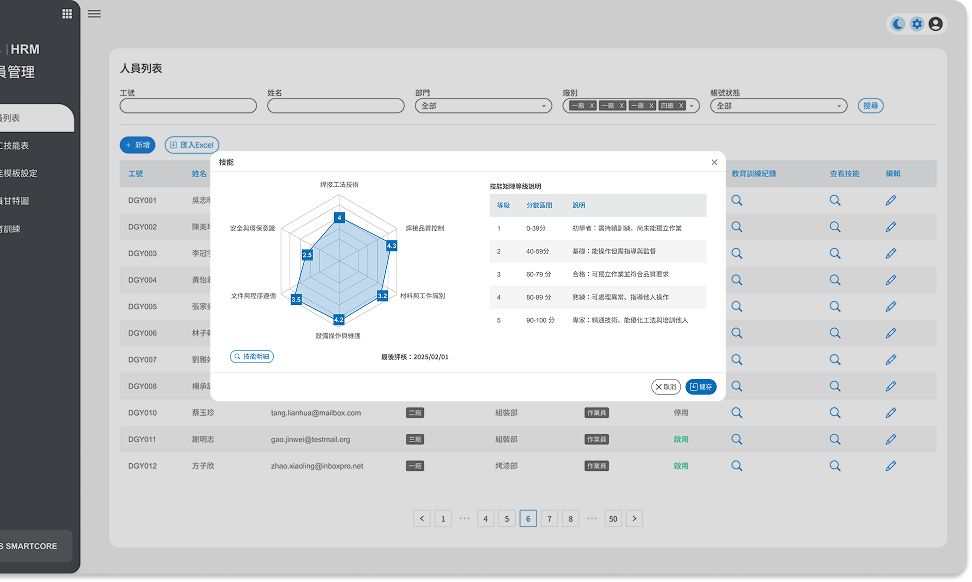

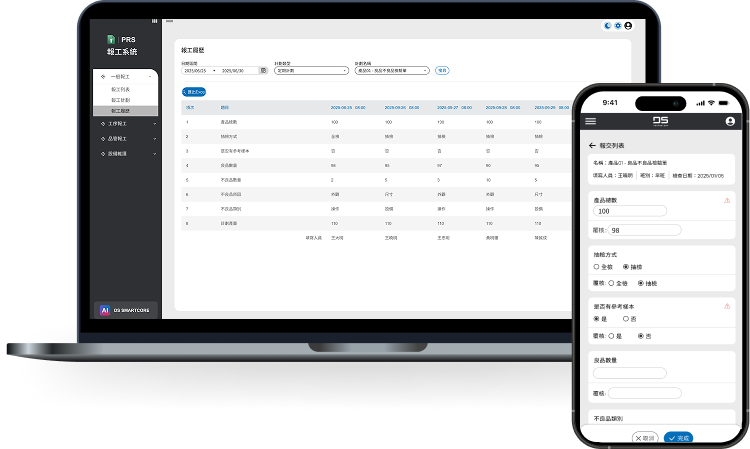

Integrates personnel data, skill qualifications, onboarding conditions, and shift records as the basis for WOMS-APS labor resources, assists in judging labor availability, assignment conditions and qualification restrictions, avoids unqualified personnel on line, and ensures scheduling considers both production needs and compliance for stable operation.

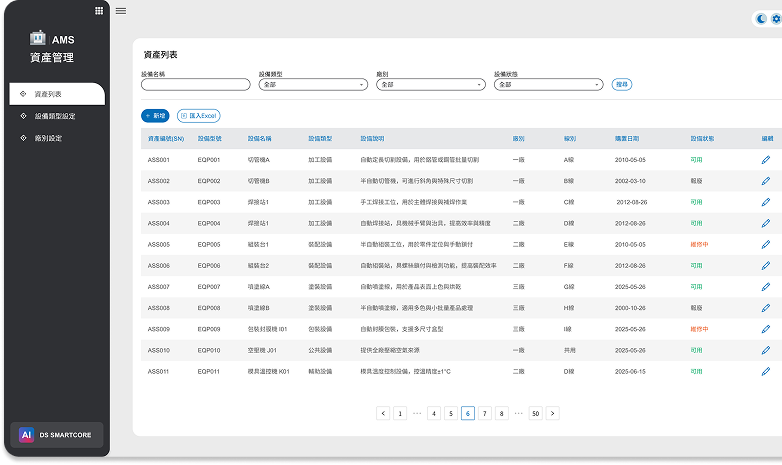

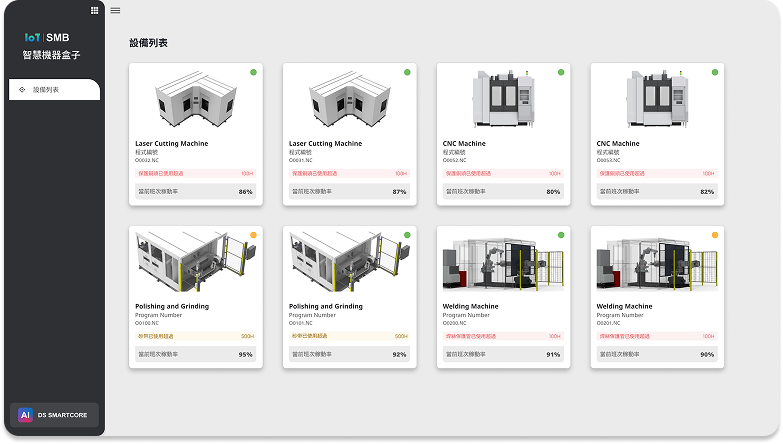

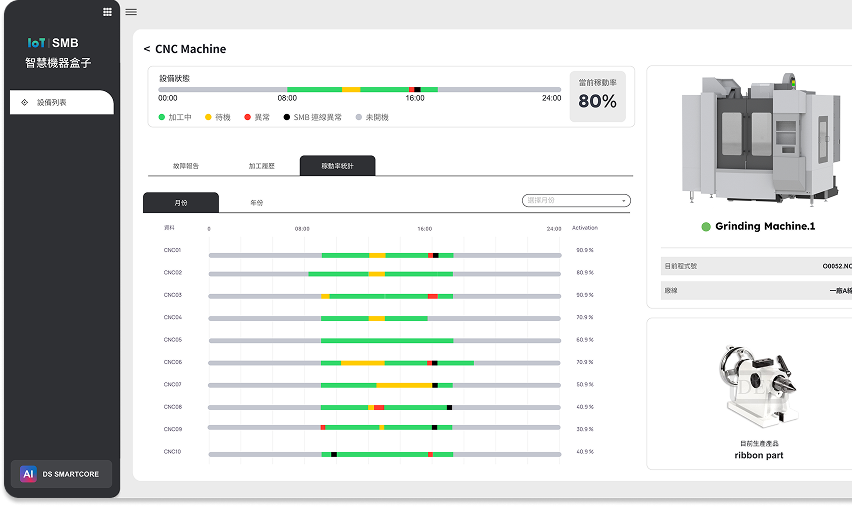

Integrates equipment records, maintenance logs, status information, and utilization data as the foundation for WOMS-APS equipment availability judgment and operation assignment, helping scheduling avoid unavailable equipment for stable production rhythm and improved equipment efficiency.

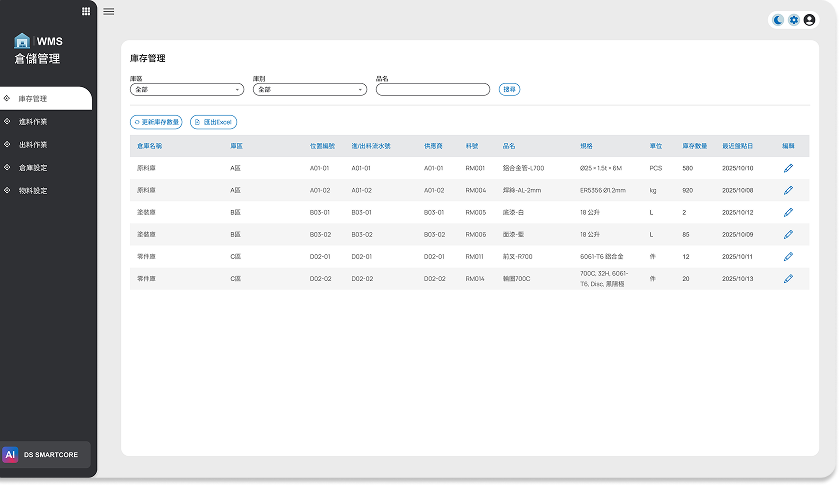

Integrates inventory, batch, and in/out records as the basis for WOMS-APS to determine material availability, scheduling, and issuing requirements, ensuring uninterrupted orders and stable production flows.

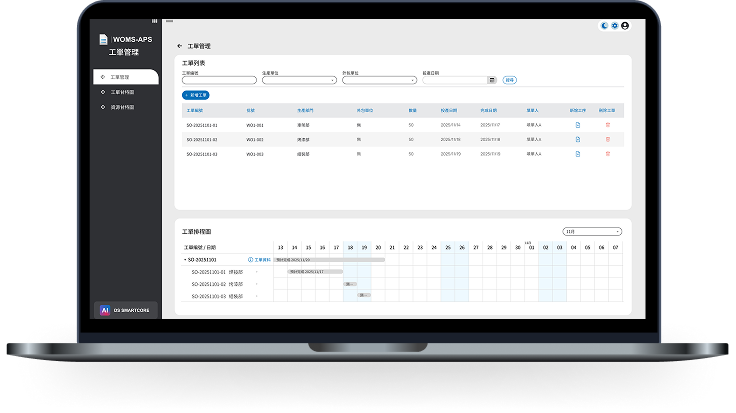

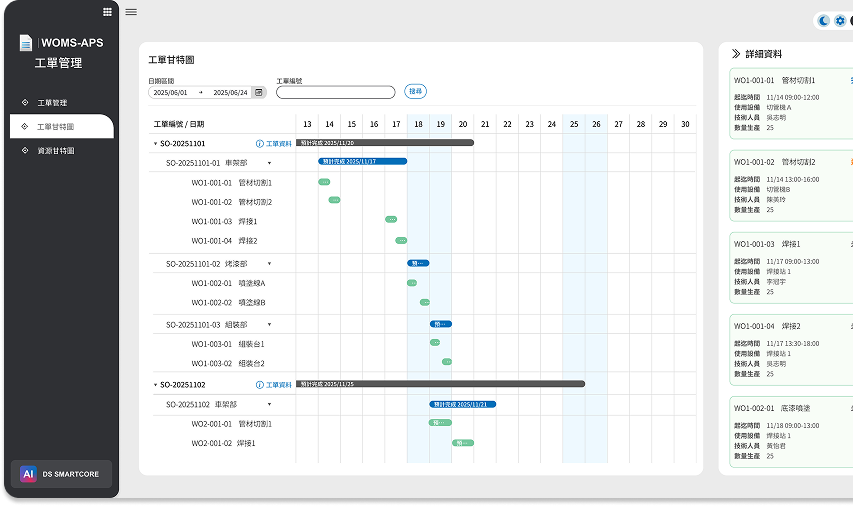

Focusing on executable scheduling, supports work order creation, process breakdown, and setup, real-time checks for labor, equipment, and material restrictions to avoid releasing infeasible orders.

Provides deadline feasibility forecast and conflict alerts, and auto-includes abnormal impact in schedule calculations; schedule instantly updates to match site status, improving reliability and transparency.

Feeds back process output, operation hours, and abnormal info for WOMS-APS to update work order progress, capacity analysis, and rescheduling, ensuring progress is visible and expected, avoiding delays, and improving manufacturing efficiency.

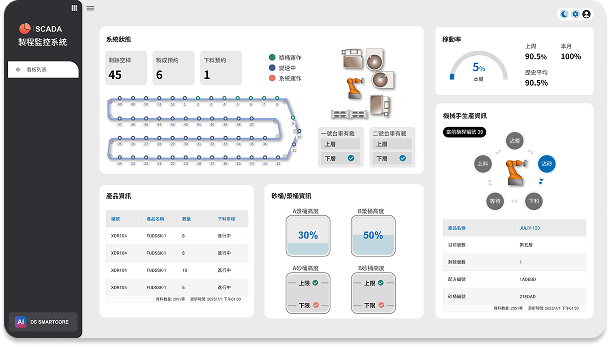

Collects equipment connectivity data, operational status, signal measurement, and warning information for WOMS-APS to judge equipment availability, process arrangement, and capacity estimation, ensuring schedules reflect real equipment status and reducing downtime risk.

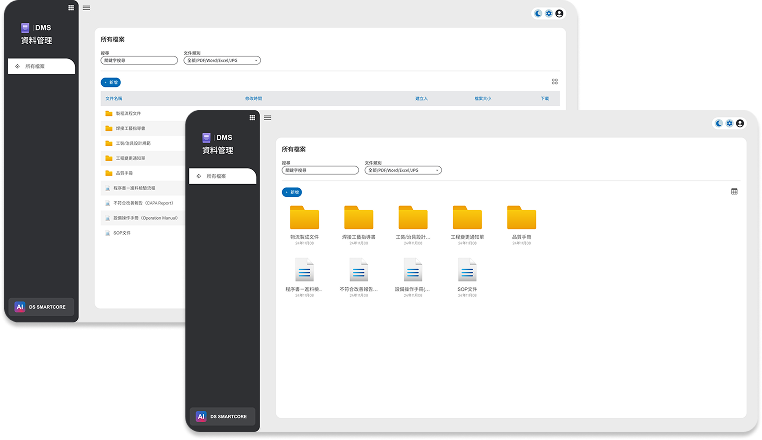

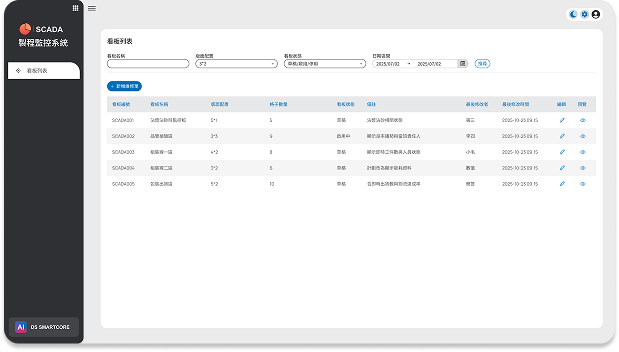

Manages manufacturing documents, SOP, drawings, and version control to ensure the shop always uses correct and latest documents, avoiding errors, and building traceable change history for manufacturing consistency and standardization.

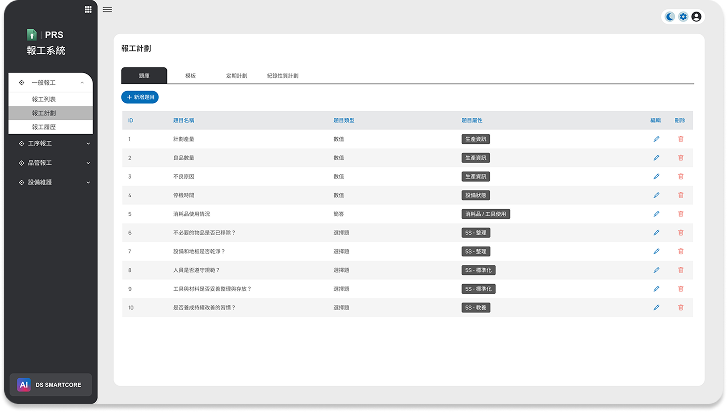

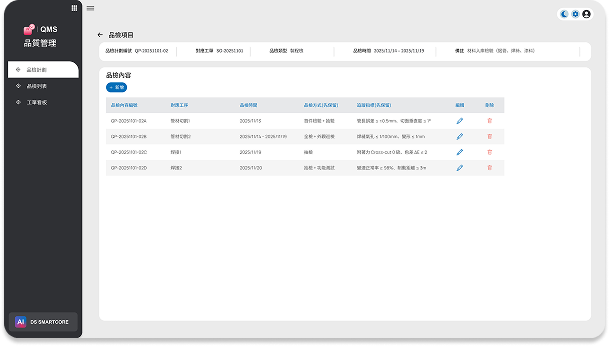

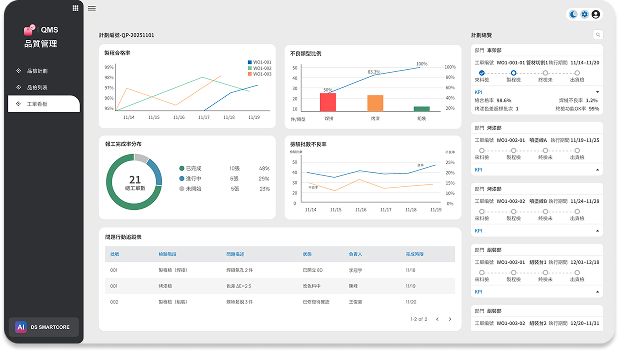

Manages process and finished product quality inspection and abnormality handling, with full inspection, tracking, and improvement processes to guarantee product consistency and stability. Quality data syncs with MES for real-time adjustment and lower defect ratio, building predictable, stable quality.

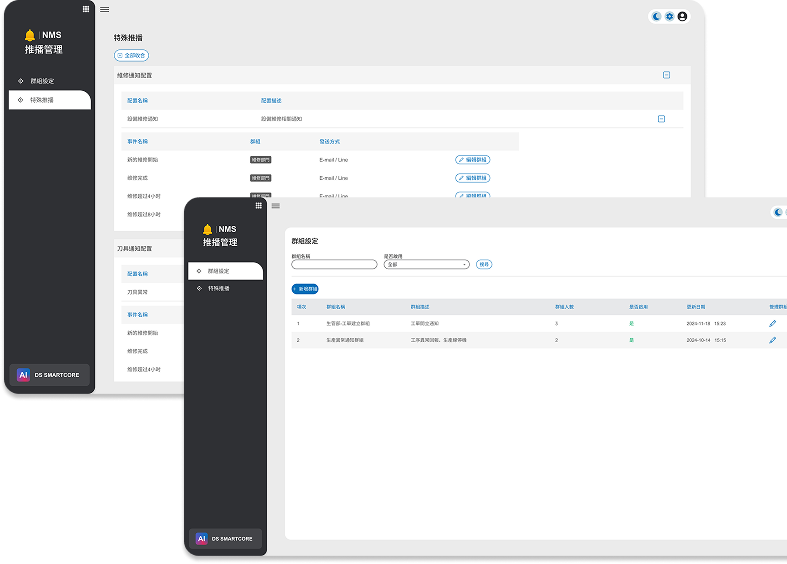

Provides instant notifications and event push, delivering key info like order changes, shortages, equipment anomalies, and quality alerts to relevant staff for rapid response and stable production.

Real-time collection of equipment, process, environment, and energy data gives complete production visibility. The system monitors electricity, air pressure, and energy use, integrates energy info into ESG management, and helps enterprises achieve sustainability.

Provides MES-required equipment utilization, environment parameters, and abnormal data for stable, safe, and traceable production.

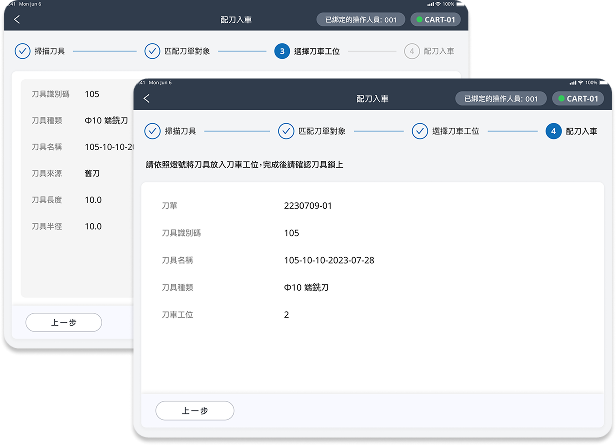

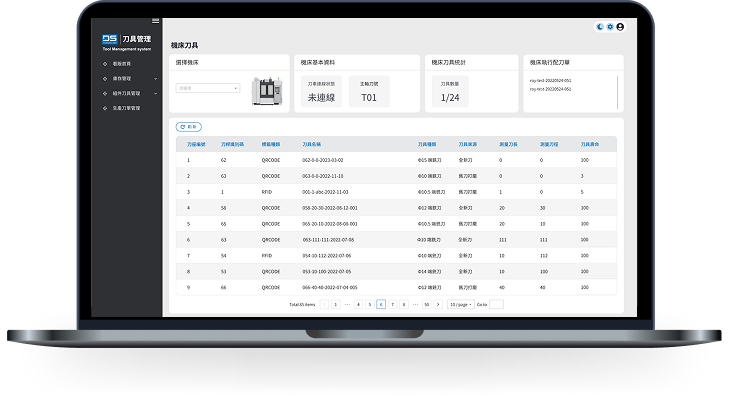

DS Tool Management focuses on lifespan, usage monitoring, and maintenance tracking, integrating intelligent tool delivery and machine communication with full RFID/QR code monitoring. Ensures the right tools are at the right machine, in the right way, reducing cost, avoiding dimension errors, scrap, and downtime, and improving yield.