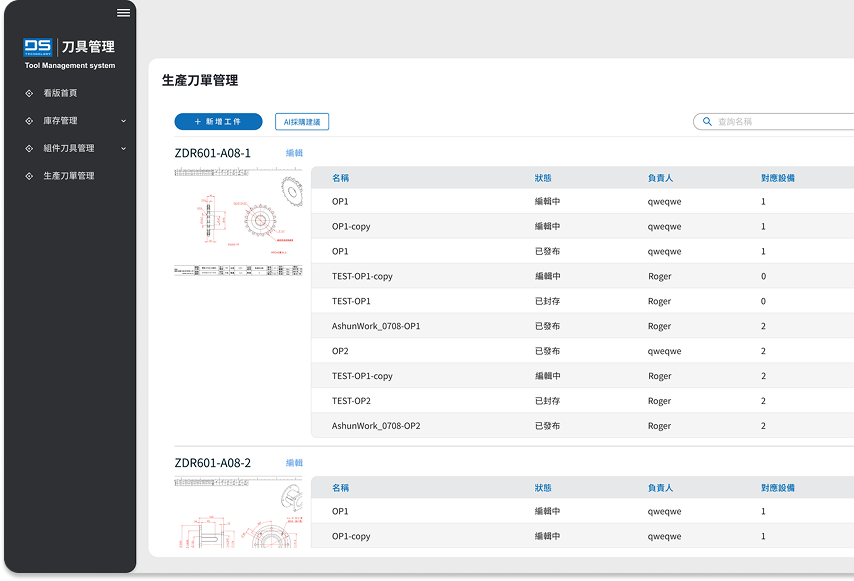

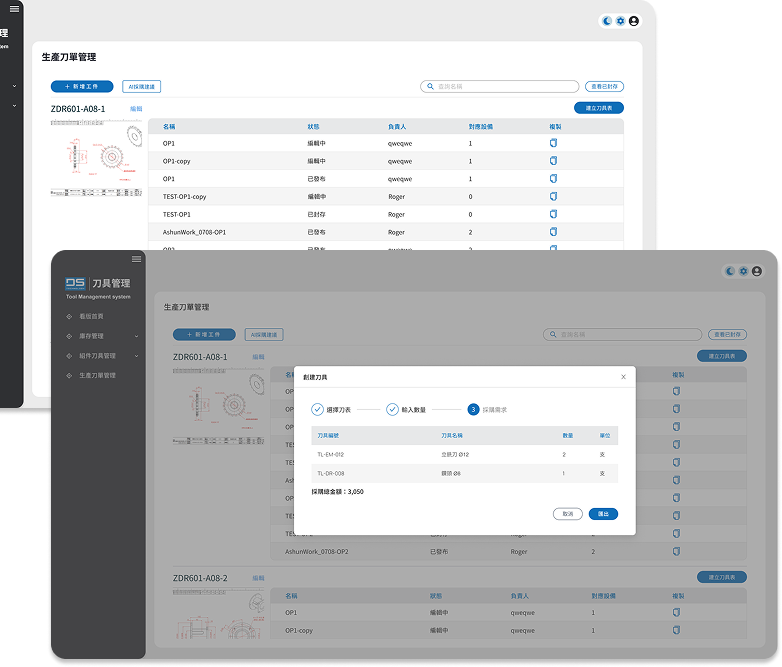

Through test cut operations, tool and insert specifications, benchmark life, and machining parameters are established, creating a standardized tool list for consistent tool configuration and use across all work orders and processes.

The system expands tools and insert configurations needed for each process step based on standardized tool tables for the workpiece, combines stock levels, life, and usage records, and provides restocking and procurement suggestions to maintain machining continuity and reduce shortage risks.

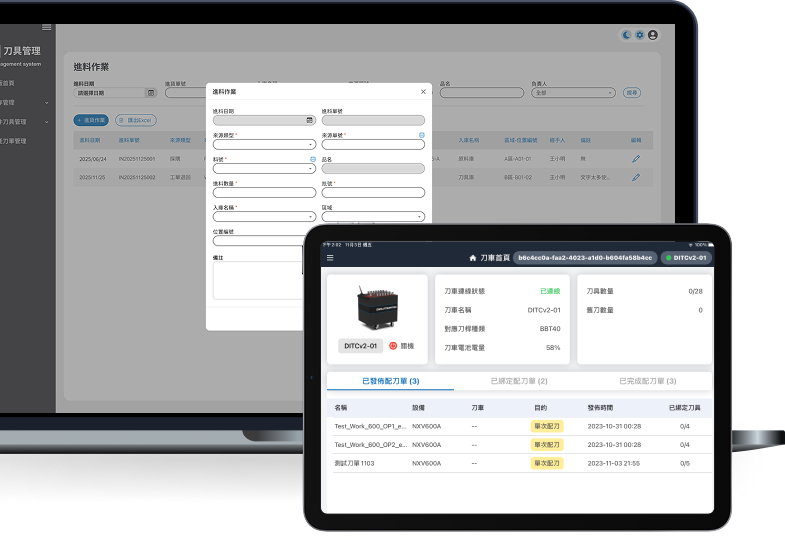

Based on the standard tool list and expanded requirements, inserts can be stored in the tool room or smart vending machines or both. The system creates insert batches, life benchmarks, and inventory quantities upon storage to support subsequent issuance, usage control, and restocking management.

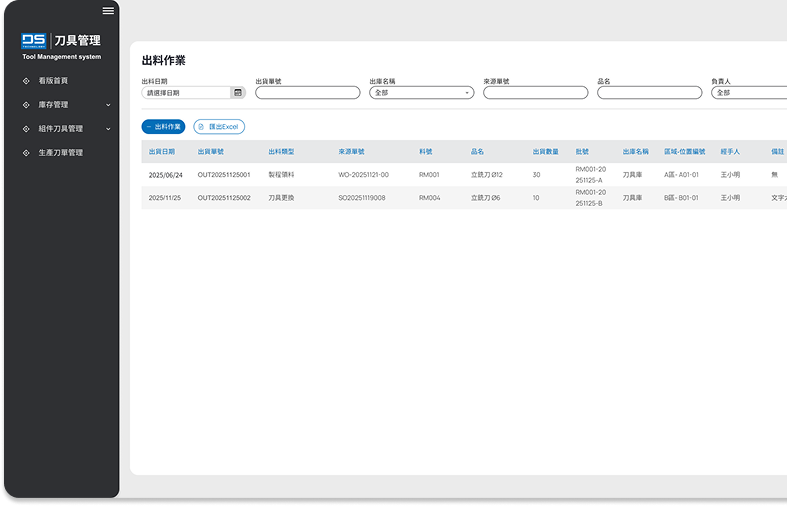

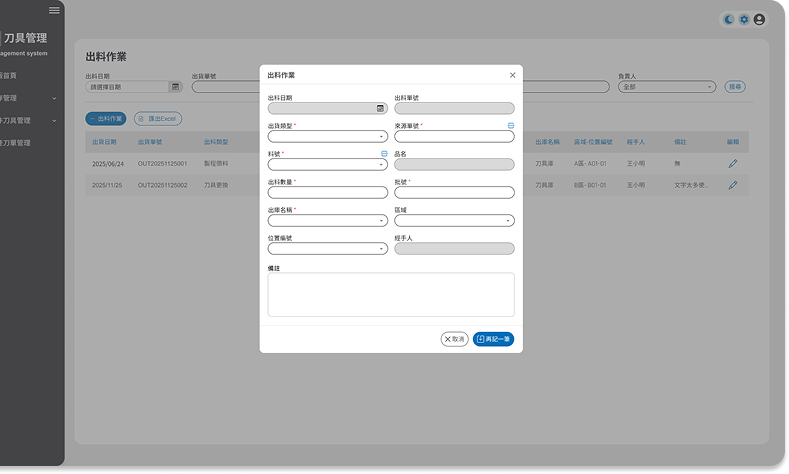

Based on the standard tool list and expanded requirements for the workpiece, inserts and consumables can be issued by tool room staff or vending machines. The system records complete operator, item, quantity, and batch data for each issuance to ensure full traceability for assembly, usage, and tool life tracking.

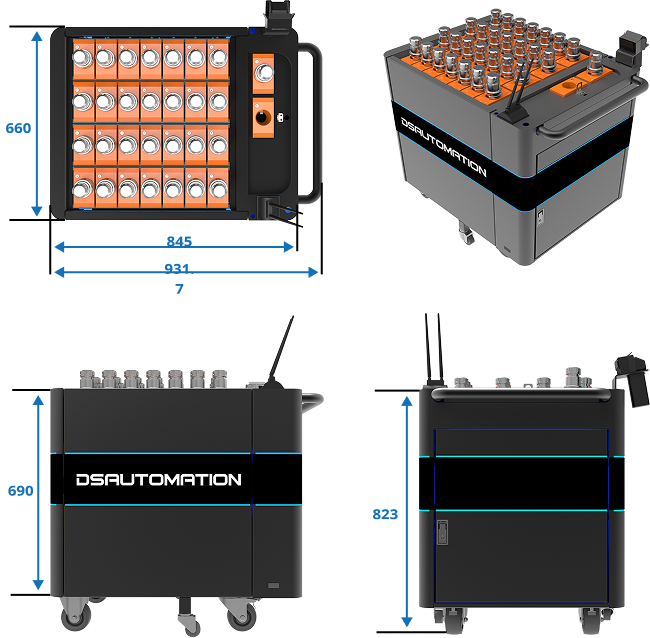

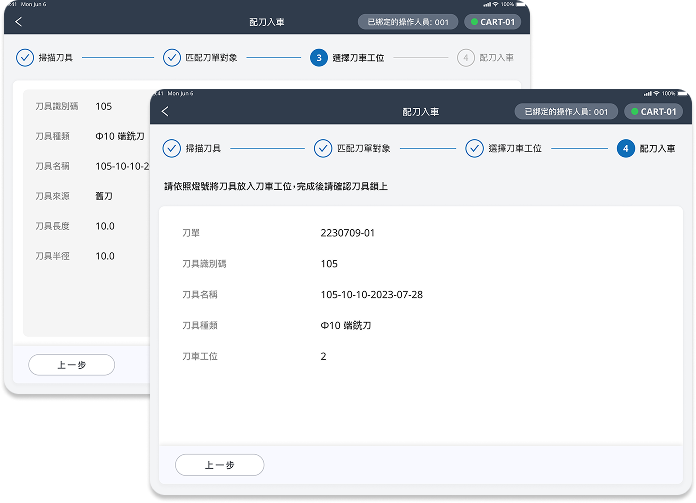

The smart tool cart delivers tools according to delivery orders, scanning the machine’s QR code before mounting to confirm the target machine and match tool identities and positions, ensuring tools are delivered to the correct machine and position according to the standard table and machine status, preventing incorrect or misplaced tools.

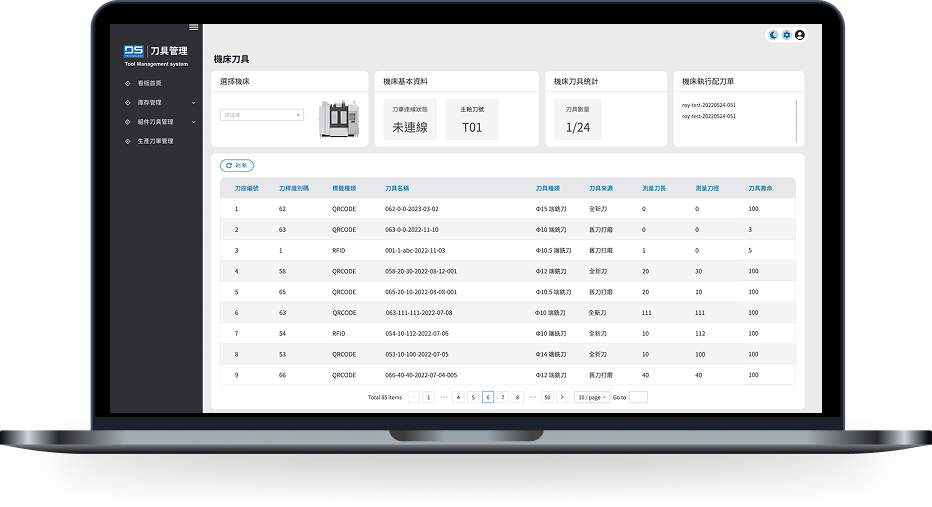

Before mounting, the CNC compares tool code, tool life, and corresponding tool table info and only allows correct tools to be mounted; after mounting, system auto-imports tool length and diameter measured by tool measuring instrument into the CNC, ensuring tool recognition and compensation settings are consistent while preventing manual input errors and improving machining stability.

System continually monitors tool life and records tool changes, regrinding, and restocking status; cumulative usage and life data serve as references for tool life improvement and machining parameter optimization, forming complete tool life cycle management.