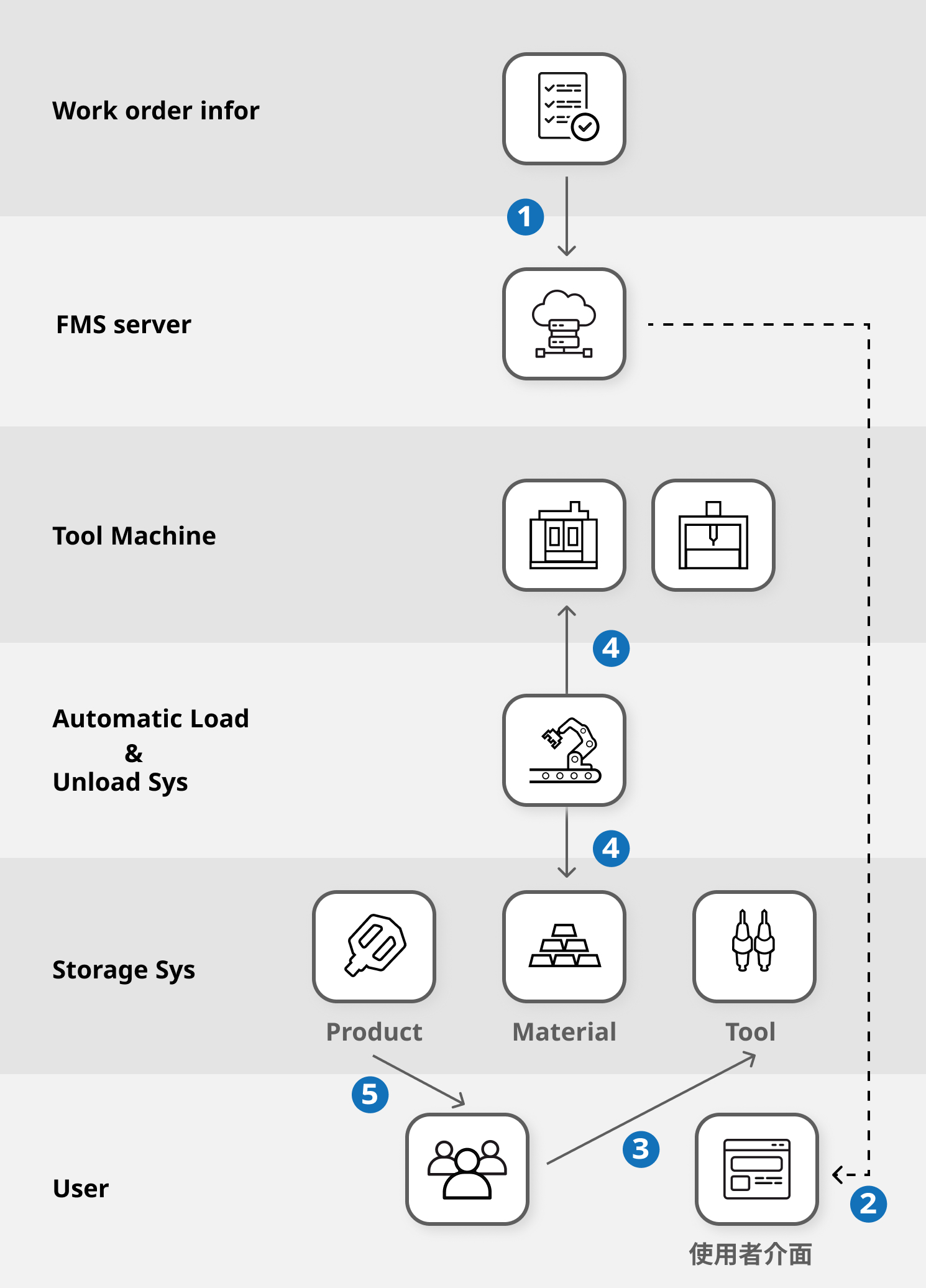

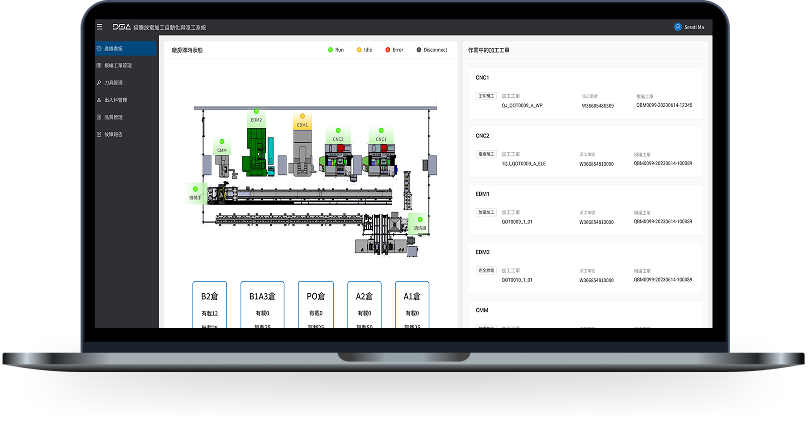

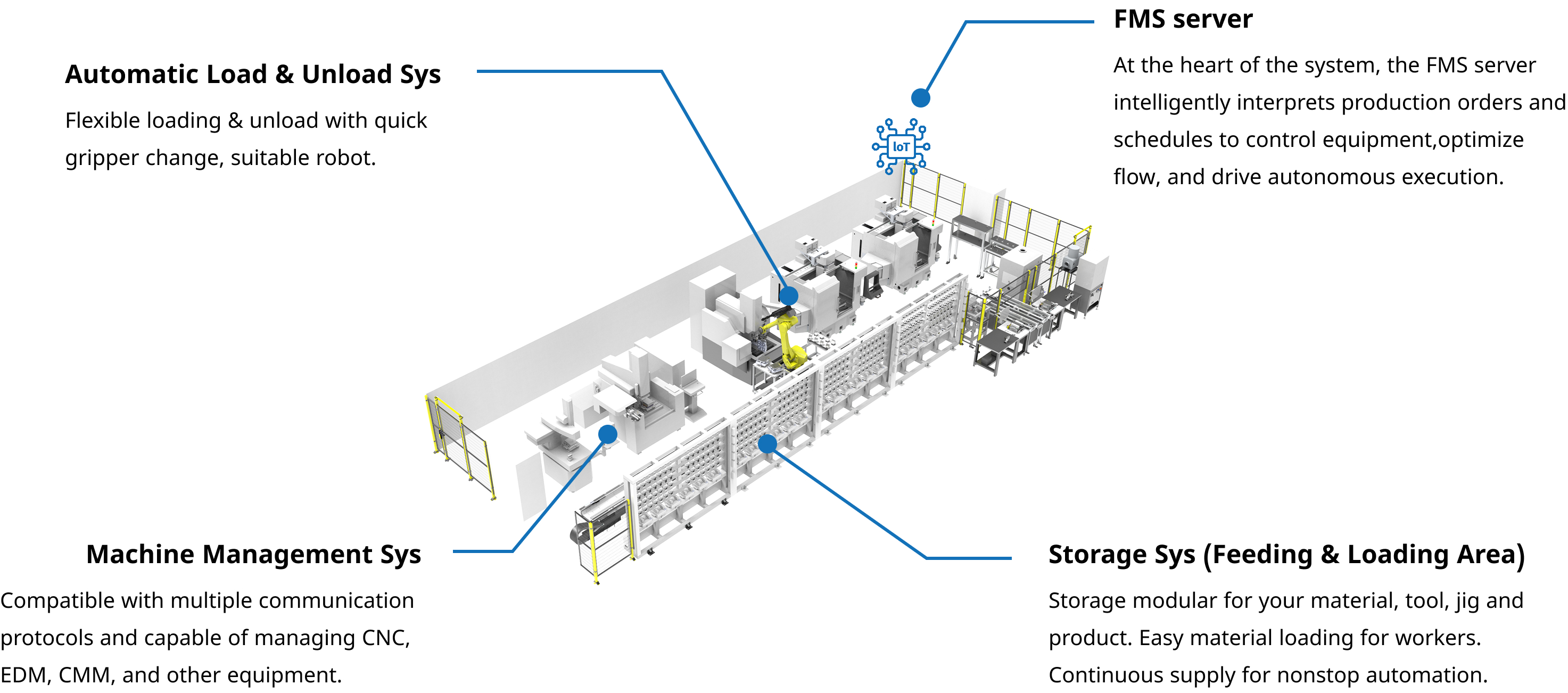

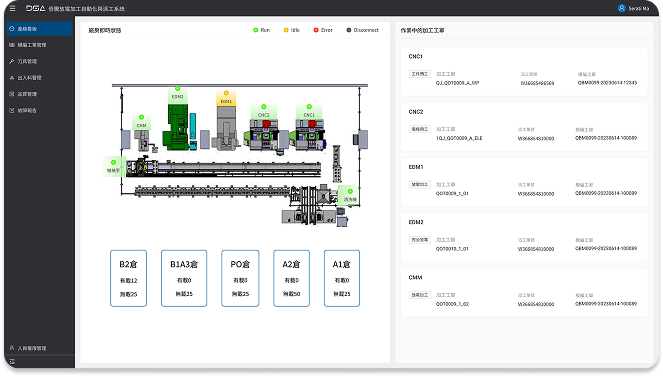

Our FMS system operates with a workflow of'Work Order Data → FMS Server → Scheduling and Program Issuance → Human-Machine Collaborative Material/Part/Tool Preparation → Automated Machining and Inspection → Finished Product Storage Management',supplemented by data monitoring and user-friendly interfaces to achieve full automation from order to shipment, ensure fast recovery from anomalies, and output data for production summary.

Receive work orders and automatically decompose machining steps, tool, and material requirements.

Automatically schedule based on equipment status and priorities, issuing CNC programs to machines.

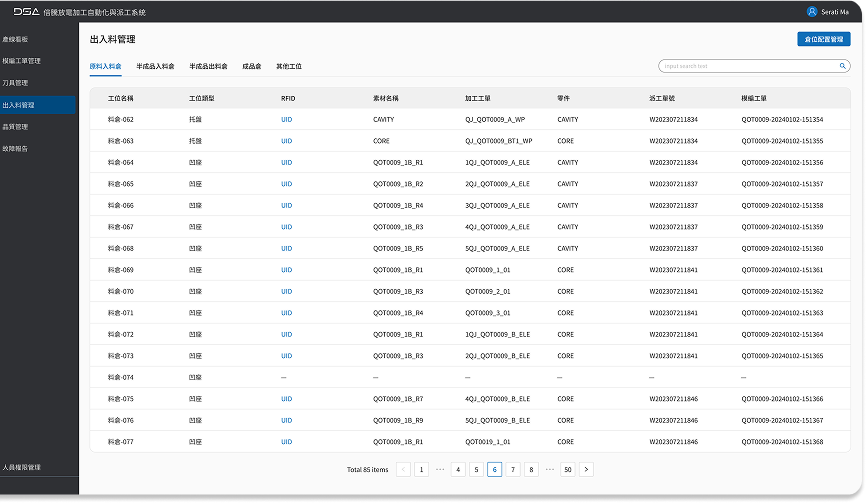

Operators, robots, and automated load/unload systems prepare production materials in advance.

Machines process automatically per schedule, reporting status, tool info, and progress; measurement results are also returned automatically to decide Pass, Rework, or NG isolation.

Finished products are placed in appropriate storage locations, prompting operators for timely removal.

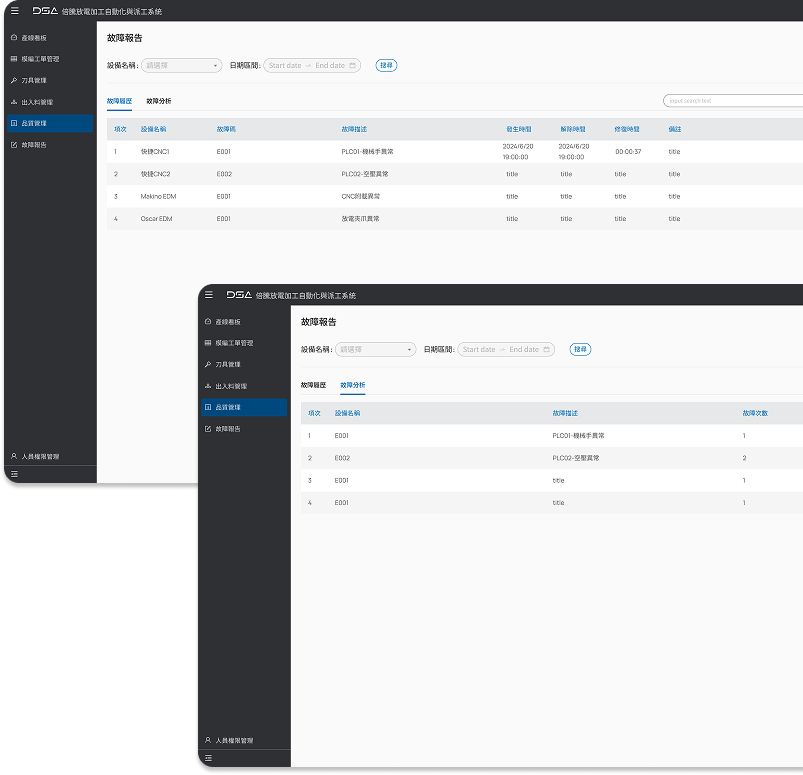

Detect equipment, tool, or quality anomalies, and auto-adjust schedule or issue alerts.

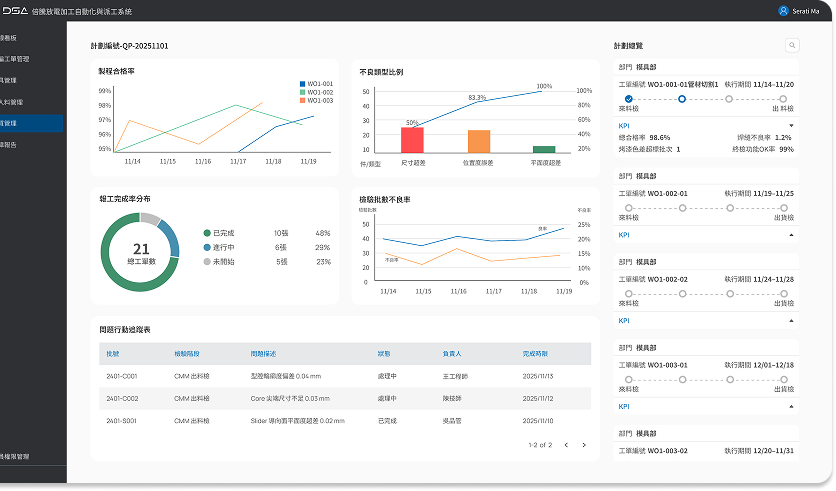

Provide machining status, yield, utilization, and reports for production optimization.

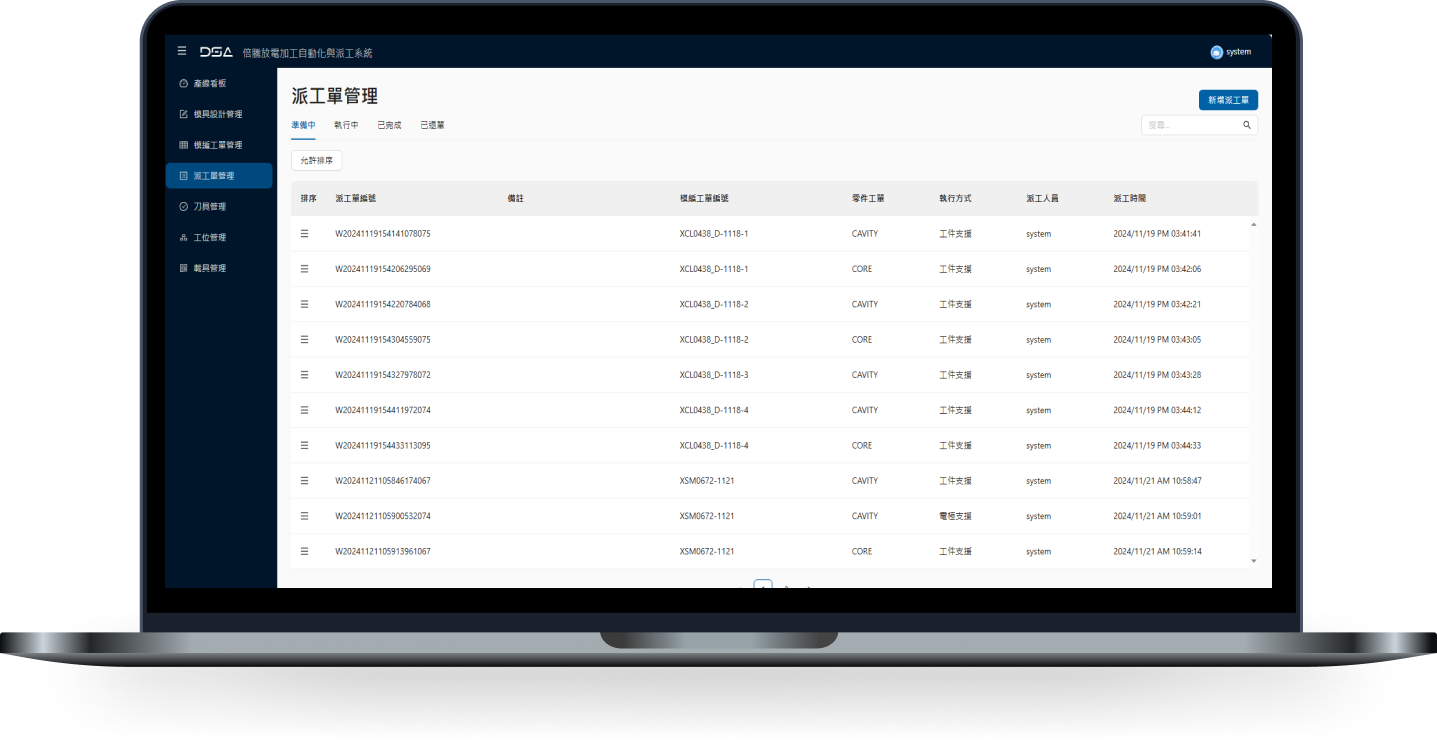

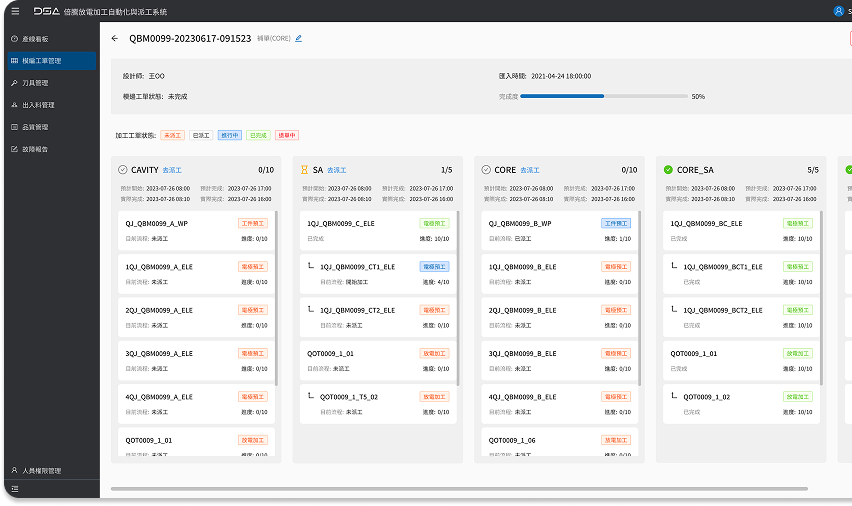

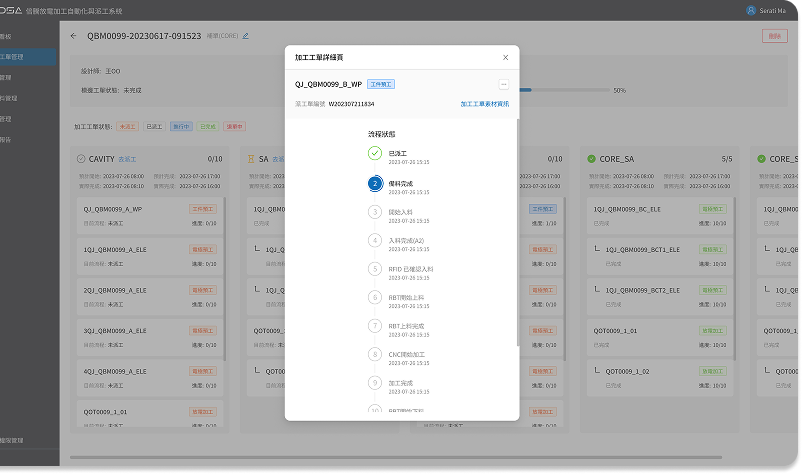

After work order import, the system expands component and part requirements. Users specify processing equipment and confirm material, tool, fixture, and procedure completeness to ensure executable work orders.

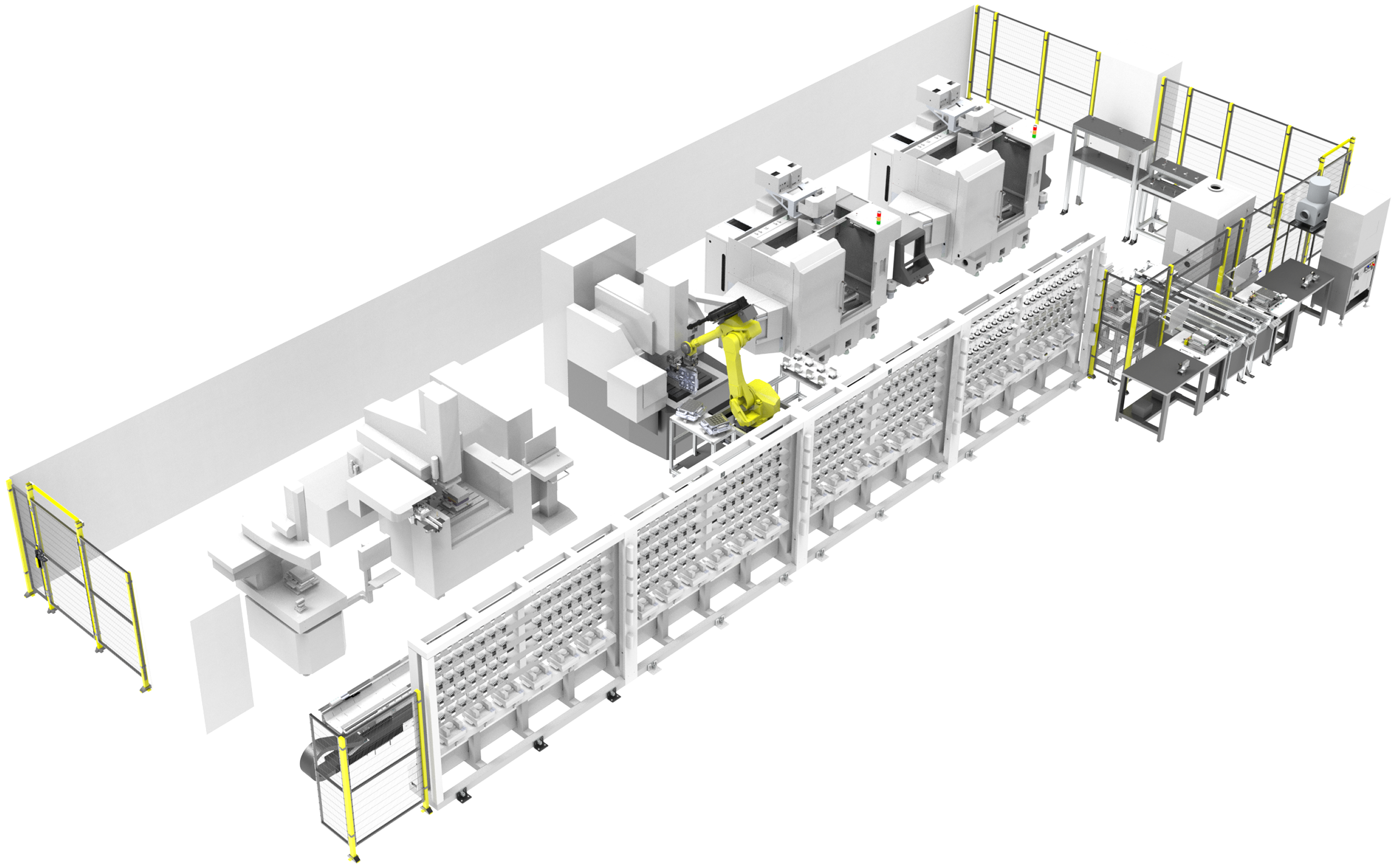

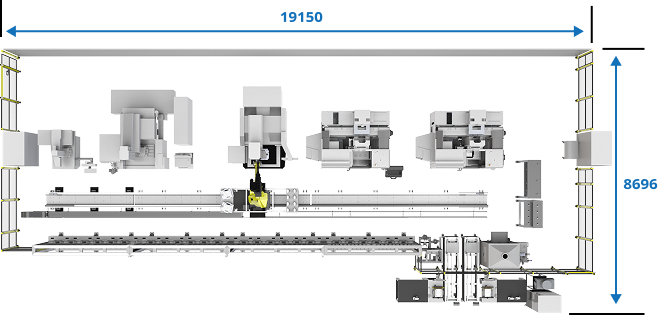

FMS creates optimal schedules per work order, sending validated CNC/EDM programs and automation procedures to machines for continuous and stable machining.

Automation uses robots, cleaning stations, tool management, and fixture switching to keep workpieces and tools continuously flowing with high efficiency and stable quality in machining and handling.

Equipment automatically executes CNC/EDM processes by schedule, reporting real-time status, tool info, and production progress to ensure a stable and traceable process.

Integrates CMM, optical, and measurement station data. Measurement results feed back to FMS and machines in real time, enabling full-process quality monitoring, anomaly alerts, and traceability from first piece to mass production, ensuring precision and consistency.

The system detects production anomalies in real time and automatically adjusts schedules, replenishes resources, or switches machines, ensuring uninterrupted production and reduced quality risks through fast recovery processes.

Real-time data and production reports monitor machining progress, equipment utilization, and quality, helping managers make quick decisions and optimize capacity.